Jubilee Metals: upgraded Roan concentrator is fully operational

Jubilee Metals reports significant progress across its Zambia portfolio which has in place all the assets it needs to maintain the momentum on our copper expansion strategy. By dedicating its existing processing capacity at Roan to a combination of third-party sourced higher-grade mined material and process tailings while advancing our Munkoyo and Project G mining operations to feed an expanded Sable, Jubilee Metals is building a robust and stable copper production profile. In addition, it is expanding its copper exploration footprint and advancing its Large Waste project.

Leon Coetzer, Chief Executive Officer said: “The energy related challenges we faced earlier this year, though difficult, have helped us emerge with a clearer, more focused strategy backed by secure power supply and higher value material supply agreements. This operational focus, prioritising run-of-mine and previously mined materials, closely resembles the successful evolution of our South African chrome and PGM operations albeit with an integrated portfolio of our own feedstock supply.

We are excited to leverage our unique capabilities in processing transitional copper reefs, available in vast quantities, and look forward to delivering clear guidance on our production under new supply agreements in the coming months. This also fits into our thinking of seeking a mining joint venture partner at our mineral assets to ensure management’s focus can remain on processing. Our commitment remains to scale operations in a non-dilutive, capital-efficient, and sustainable manner as we advance toward our medium-term targets.”

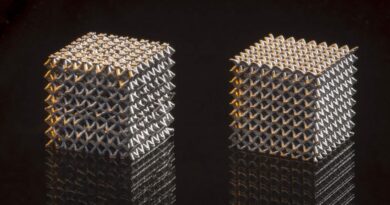

- The upgraded Roan concentrator is fully operational and capitalised and exceeded its targeted production for the month of July 2025 reaching 384t of copper units for the month of July 2025 and is ahead of the targeted production rate of 350t in August 2025.

- Munkoyo open pit operation’s drilling program has commenced with the initial 8 drill holes completed in partnership with an established mining and exploration company. Drilling results are being reviewed by a competent person and the results will be released in due course.

- Early indication from the drilling campaign suggests the potential to combine pits 2 to 4 into a single large open pit to offer increased mining flexibility and increased throughput to sustain the targeted high-grade ROM of between 6 500 to 8 500tpm at 2.5% Cu.

- The new pit designs factored in the drilling results of the copper sulphide ore body discovery below the near surface copper oxide layer currently being targeted.

- Discussions are in progress with an established mining and exploration partner to implement the further expanded Munkoyo and develop Project G while undertaking an exploration program of the newly secured exploration properties within the area.

- Copper production for H1 FY2025 was severely impacted by the power and infrastructure challenges, previously reported. Roan was placed under care and maintenance for an extended period while power security was resolved and process upgrades successfully completed to allow for the simultaneous processing of high-grade copper materials and tailings.

- On the back of a successful Roan restart, copper units production for H2 FY2025 reached 757 tonnes (H1 FY2025: 1 454 tonnes) (Guidance for H1 FY2026 of 2 300 tonnes) with annual production for FY2025 reaching 2 211 tonnes (Guidance for FY2026 of 5 100 tonnes)

Zambia production guidance for FY2026

Copper unit production guidance for H1 FY2026 of 2 300 tonnes and 5 100 for the full year FY2026. Further capital dependent projects which are currently underway and being targeted to commence within FY2026, offer the potential to increase annual copper production by approximately 10 000 tonnes as follows:

- Onsite Munkoyo processing unit – 1 440 tonnes per annum;

- Project G processing unit – 1 320 tonnes per annum;

- Refining at Roan – 2 544 tonnes per annum; and

- Two processing modules at the Large Waste Tailings dump – 5 500 tonnes per annum.