Rio Tinto sells its first aluminium-scandium alloy for 3D printing

MONTREAL – Rio Tinto has signed an agreement to provide a first commercial batch of high-performance aluminium-scandium alloy from its North American operations to Amaero, a leader in metal additive manufacturing.

This first sale is being delivered through Rio Tinto’s unique position as a producer of both aluminium and scandium, and its technical capability to develop specialised alloys.

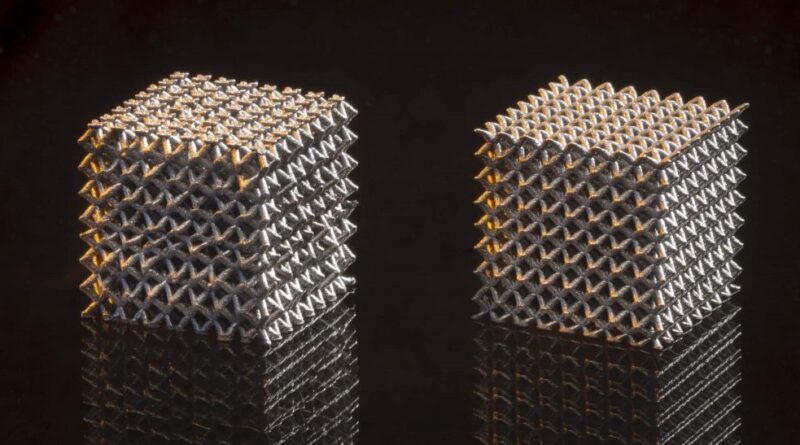

Under the agreement, Rio Tinto will deliver alloy billets made of responsibly produced, low carbon aluminium from its hydro-powered Canadian smelters and high purity scandium oxide from its Rio Tinto Fer et Titane (RTFT) metallurgical complex in Sorel-Tracy, Quebec. The billets will be processed by Amaero into powder for 3D printing and offered to the market for high temperature applications.

The scandium oxide will be supplied from a new plant Rio Tinto is building in Sorel-Tracy, Quebec, bringing the first North American supply source to the world. The plant will use an innovative recovery process developed by Rio Tinto scientists to extract high purity scandium oxide from the waste streams of titanium dioxide production, without the need for any additional mining.

The companies will also collaborate to develop the supply chain for Amaero’s high performance, High Operating Temperature Aluminium Alloy, “Amaero HOT Al”, and commercialise this lightweight material for applications in the aerospace, defence and other industries.

Rio Tinto Aluminium vice president Sales and Marketing Tolga Egrilmezer said: “As a global leader in aluminium and the first producer of high-quality scandium oxide in North America, Rio Tinto is uniquely positioned to provide a secure source of aluminium-scandium alloy to the market. Aluminium-scandium alloy is the material of choice where a lightweight, high-strength material with thermal resistance and good welding properties is needed, such as for defence and aerospace applications. This first sale demonstrates our ability to develop products that meet our customers’ needs, drawing on our technical expertise and world class assets.”

Amaero chief executive officer Barrie Finnin said: “We are very pleased to enter this Agreement with Rio Tinto to purchase the first commercial batch of aluminium scandium alloy from a North American source. This is an important step in the commercialisation of this high performance alloy that will be used in our breakthrough 3D metal printing technology. We look forward to working with Rio Tinto to progress the production of the alloy so we can commence the qualification process with key customers in the aerospace sector and other industries.”

Rio Tinto is an industry leader in responsible aluminium production. In 2016, Rio Tinto launched RenewAl, the world’s first certified low CO2 primary aluminium brand. It has helped to pioneer responsible production standards for the global industry as a founding member of the Aluminium Stewardship Initiative (ASI), becoming the first producer to offer ASI Aluminium in 2018. Earlier this year, Rio Tinto also launched START, the first sustainability label for aluminium delivered to customers through blockchain technology, enabling them to differentiate between end products based on their environmental, social and governance credentials.

Amaero International Limited is an Australian based company that manufactures large format complex components in metal with laser-based additive manufacturing processes, commonly known as 3D printing.

Amaero has worked with many of the world’s leading manufacturers of aerospace and defence products in both an R&D and manufacturing capability and has a demonstrated ability to deliver aviation and military specification 3D printed alloy critical operation components.

Amaero was established with the support of Monash University in 2013 to take advantage of commercial opportunities identified by the Monash Centre for Additive Manufacturing (MCAM). Amaero is co-located with MCAM in Melbourne Australia. It operates two additional facilities, in Adelaide, South Australia, and El Segundo, California, USA.