Lualaba Copper Smelter restarts following scheduled maintenance

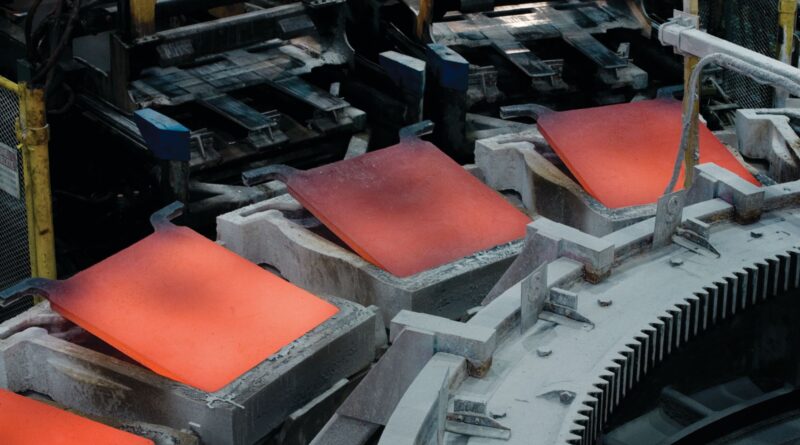

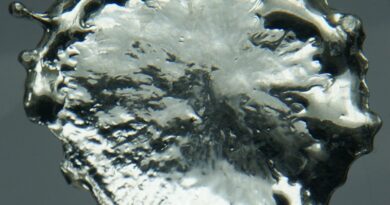

The Lualaba Copper Smelter, located approximately 50 kilometres from Kamoa-Kakula, completed its scheduled maintenance in early September. The transportation of copper concentrates to the facility has resumed, as well as the export of its blister copper (approximately 99% contained copper). The Lualaba Copper Smelter is expected to treat approximately 120,000 tonnes of copper concentrates from Kamoa Copper in 2022.

In line with previous disclosures, Kamoa Copper is in the process of implementing several initiatives to optimize the transportation of copper products, following higher logistics costs announced in Q2 2022 due to a significant increase in volumes shipped.

The restart of the Lualaba Copper Smelter will assist in reducing overall shipping volumes, as the export of blister copper incurs lower logistics costs per unit of copper compared to copper concentrate. While the logistics optimization initiatives are underway, Kamoa Copper and other operators have continued to experience disruption including periodic border congestion and occasional industrial action by truck drivers.

Kamoa-Kakula’s Phase 3 will consist of two new underground mines known as Kamoa 1 and Kamoa 2, located 10 kilometres north of the existing Phase 1 and Phase 2 concentrator plants. A new, 5-million-tonne-per-annum concentrator plant will also be established adjacent to the two new Kamoa mines. In addition, a 500,000-tonne-per-annum, direct-to-blister flash smelter will be constructed adjacent to the existing Phase 1 and Phase 2 concentrator plants. The associated power and surface infrastructure constructed for Phase 3 will be designed to support future expansions of the Kamoa-Kakula Mining Complex.

Construction now is complete on the Phase 3 box cut and decline ramp at the Kamoa 1 and Kamoa 2 underground mines, while excavation of the twin declines to access the new mining areas is advancing well. Construction works for the ramp, cut-off drains, and water-collection sumps also now is complete.

Basic engineering design for the entire Phase 3 expansion project is complete, with procurement activities well advanced. Bush clearing and terracing work for the 5-million-tonne-per-annum concentrator plant and associated surface infrastructure has started. Earthworks and civils contracts have been placed.

Upon commencement of Phase 3 production, the Kamoa-Kakula Mining Complex will have a processing capacity in excess of 14 million tonnes per annum. Phase 3 is expected to increase copper production capacity to approximately 600,000 tonnes per annum, with commissioning expected by the fourth quarter of 2024. This production rate will position the Kamoa-Kakula Mining Complex as the third-largest copper mining operation in the world.

Kamoa-Kakula’s Phase 3 expansion also includes the refurbishment of turbine #5 at the Inga 2 hydroelectric power station. The turbine will supply an additional 178-megawatts of clean hydroelectric power to the national grid, which is sufficient to meet the power requirements of the Phase 3 concentrator, the direct-to-blister flash smelter, as well as providing spare capacity for future expansions. The blister anode copper produced from Kamoa-Kakula’s smelter is expected to be one of the lowest carbon emitters per tonne of copper produced in the world.

The Kamoa-Kakula smelter is designed to use technology supplied by Metso Outotec of Espoo, Finland, and to meet the International Finance Corporation’s (IFC) emissions standards. The smelter has been sized to process much of the copper concentrate that is expected to be produced by Kamoa-Kakula’s Phase 1, 2 and 3 concentrators.

Earthworks excavation is now approximately 60% complete and progressing well at the smelter site, adjacent to Kamoa-Kakula’s Phase 1 and Phase 2 concentrator plants. Civil works have also commenced.