Making tin oxide nanoparticles for high-tech using plants

Making tin oxide nanoparticles for high-tech using plants Scientists have pioneered a green synthesis method for producing tin (IV) oxide nanoparticles (SnO₂NPs) using extracts from edible plants, offering an eco-friendly and sustainable alternative to traditional chemical processes.

SnO₂NPs are widely used in high-tech applications such as touch screens, solar panels, gas sensors, batteries, and more. In this specific example, researchers used the tin oxide to treat breast cancer. SnO2NPs were able to reduce cell viability to 43.45% meaning over 50% of breast cancer cells were terminated.Researchers from Pamukkale University in Turkey employed pre-treated, powdered Cnicus benedictus (blessed thistle) and Aronia melanocarpa (black chokeberry) extracts.

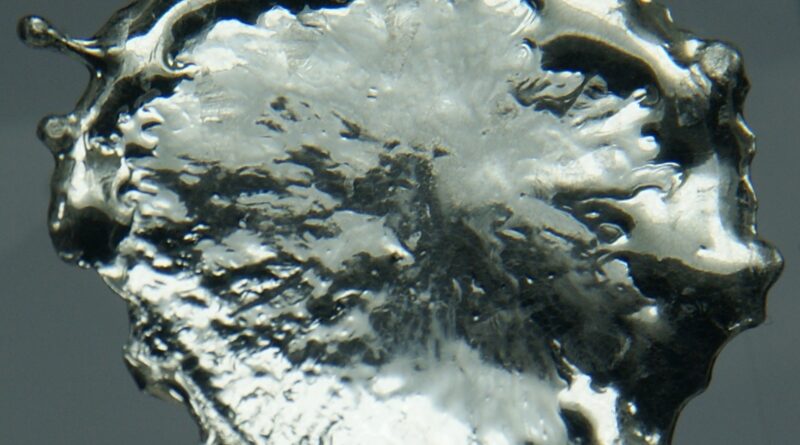

The synthesis process used the plant-based chemicals to convert stannous chloride (SnCl2·2H2O) to tin oxide, before calcination or dehydration of the product at high temperatures. Characterisation techniques such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) confirmed the successful formation of stable SnO₂ nanoparticles with distinct morphological properties.

This use of plant-based extracts eliminates the need for toxic chemicals. The process holds promise for large-scale, low-cost nanoparticle production, minimising environmental impact compared to conventional methods.