Melt Expert is champion in fine-tuning electric steelmaking processes

Athletes who excel at the 2024 Summer Olympics in Paris all have certain characteristics in common – they are precise and effective, and they showcase world-leading skills in their respective discipline. Interestingly, all of these features can also be found in Primetals Technologies’ Melt Expert electrode control system for electric arc furnaces (EAFs) and ladle furnaces (LFs).

Melt Expert customers worldwide benefit from increased productivity, reduced energy and electrode consumption, as well as lower production costs. Simply put, the leading system for optimizing melting processes is a game-changer for steel producers wanting to get the most out of their EAFs and LFs. Recently, Primetals Technologies celebrated its 100th Melt Expert installation at a customer’s site in Turkey. All of these implementations were accomplished within the last four years.

100 Melt Expert Installations

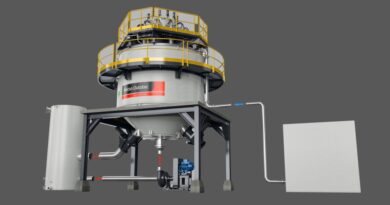

The recent Melt Expert installation at an EAF in Turkey is a significant milestone. Melt Expert enables dynamic control over the melting process, increases process stability, and helps the meltshop staff to overcome scrap fluctuations. The integrated Foaming Slag Manager and the Dynamic Spray Cooling model ensure additional process control and efficiency improvements. The comprehensive diagnostics package provides operators with detailed melt diagnostics, electrode consumption figures, and key performance indicators via an intuitive dashboard.

Precision and Control in Melting Processes

Automation experts from Primetals Technologies have spent years of hard work to perfecting Melt Expert’s performance, making it the true champion in the field of electrode control systems for EAFs and LFs. Melt Expert offers numerous benefits to process engineers, plant managers, and maintenance personnel – it significantly increases furnace productivity by addressing the common problem of reduced throughput and efficiency in steelmaking processes. It also tackles the high energy costs associated with the melting process by lowering the consumption of electrical energy. The system ensures the accurate reproduction of a predefined melting process, solving the problem of operational inconsistency and lack of precision. Moreover, it optimizes the melting process by improving overall furnace performance and output quality.

Ensuring Peak Performance Just like sports equipment, Melt Expert must stay in shape to continuously unfold its full potential. Primetals Technologies offers worldwide service support, including on-site assistance, to keep the system and its settings optimally adjusted to changes in factors such as scrap density and quality. Service contracts provide troubleshooting support, system maintenance checks, optimization based on data analysis, and a guaranteed response time.

By signing an annual service contract, steel producers benefit from several advantages. A dedicated, expertly staffed support hotline helps to resolve any production-related issue swiftly and comprehensively. Remote live support gives specialists from Primetals Technologies immediate access to critical data for analysis and insight that may not be known to the customer.