Metso technology supplier for Ni-Co Refinery project in Vietnam

Blackstone Minerals Ltd has announced the inclusion of Metso as the technology supplier for the definitive feasibility study of the company’s pCAM (precursor cathode active material) processing plant in their Ta Khoa Refinery in Vietnam. Metso is already involved in the design of the pCAM plant and will also conduct independent pCAM test work to validate the nickel and cobalt sulphates generated during the pilot program for suitability in pCAM generation.

“Metso brings a legacy of innovation and success from the mineral processing industry to the battery industry, joining them on this journey is certainly exciting. Blackstone intends to leverage off Metso’s engineering services and know-how into the pCAM facility design, thus de-risking the Project and confirming Blackstone’s intent to be a real player in the pCAM space. Securing another world leader to the Ta Khoa Project is yet another jigsaw piece in the battery value chain puzzle. Blackstone continues to look forward to project success as it marches towards developing the greenest and most resilient nickel business in the world,” says Scott Williamson, Managing Director, at Blackstone Minerals Ltd.

“Metso is pleased to be a partner in Blackstone’s Ta Khoa Project. We are confident that our experience in nickel processing and battery metals technologies will contribute positively to the project. Many of our offerings that are planned to be used in this project are selected from our range of Planet Positive products, which are demonstrably more energy or water efficient than the industry benchmark or Metso’s previous generation products in the market, to help our customers cut their CO2 emissions and/or to achieve other sustainability priorities. We believe these are all in line with Blackstone’s objectives towards developing the greenest and most resilient nickel business in the world,” says Rudi Rautenbach, Director, Minerals Sales, Asia-Pacific, Metso.

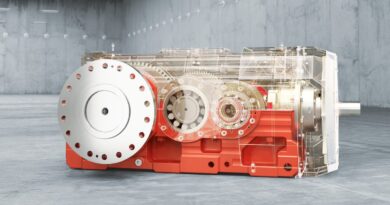

Metso provides sustainable technology and equipment for the entire lithium, nickel, and cobalt production chain from the mine to battery materials and black mass recycling with project scopes ranging from equipment packages to plant deliveries. For active cathode precursors manufacturing, Metso’s technology offering ranges from optimized raw materials selection to precipitated metal hydroxide precursor materials. Metso has its own pCAM testing facilities.

Read more about Metso’s offering for battery minerals on our website.

Blackstone Minerals is an Australian-based company focused on building an integrated battery metals processing business in Vietnam that produces the lowest emission nickel, cobalt and manganese precursor products for Asia’s growing lithium-ion battery industry.

The existing business has a modern nickel mine built to Australian standards, which successfully operated as a mechanized underground nickel mine from 2013 to 2016. This will be complemented by a larger concentrator, refinery and precursor facility to support integrated production in-country.

To unlock the flowsheet, the Company is focused on a partnership model and is collaborating with groups that are committed to sustainable mining, minimizing the carbon footprint and implementing a vertically integrated supply chain.