Modernized Finishing Mill improves reliability and efficiency

Primetals Technologies has upgraded the automation systems at the finishing mill of SAIL Bokaro’s hot-strip mill in Bokaro Steel City, Jharkhand, India. This project was completed within 26 months, one month ahead of schedule. The upgrade, featuring advanced Level 1 and Level 2 automation solutions, ensures improved quality, reliability, and efficiency for SAIL Bokaro, a key player in India’s steel industry.

Completed Ahead of Schedule

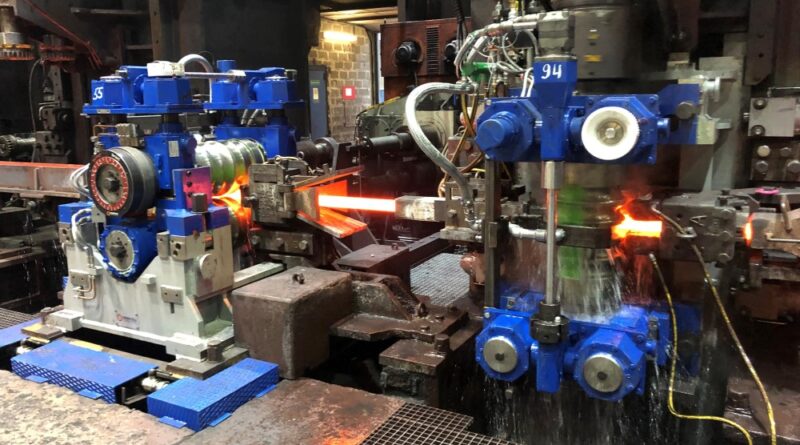

The project involved replacing obsolete automation hardware with state-of-the-art systems, including basic and process automation, flatness and thickness gauges, and a fully virtualized server infrastructure. The scope also covered the adaptation and upgrade of drive interfaces, implementation of new software, and the renewal of measurement technology for profile and flatness.

Despite an ambitious timeline, the project was completed two days ahead of a planned 20-day shutdown, thanks to meticulous planning and close collaboration between the teams of Primetals Technologies and SAIL. Additionally, all relevant mill performance targets were achieved ahead of schedule.

The modernization encompassed automation equipment for the finishing mill, cooling section, down coiler, and coil conveyor. Key technical enhancements included renewing sensors and valve stands for hydraulic adjustments.

Increased Availability

The upgraded automation system offers SAIL Bokaro several benefits, including increased availability and improved technology and functionality. The modern human-machine interface (HMI) and diagnostics system supports operators and maintenance staff with advanced and rapid troubleshooting capabilities, contributing to reduced downtime at the finishing mill. The new systems are operated on virtualized servers, ensuring smooth operations and enhanced production quality.

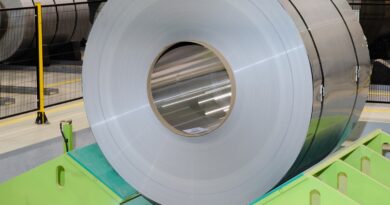

A Leading Indian Steel Producer SAIL Bokaro, a unit of the Steel Authority of India Limited (SAIL), is one of the largest steel plants in India. Established in the 1960s, the Bokaro steel plant has become a cornerstone of India’s steel production. The plant specializes in producing flat products such as hot rolled coils, hot rolled plates, cold rolled coils, and galvanized sheets, serving various industries including automotive, liquefied petroleum gas (LPG) cylinder production, and pipe and tube manufacturing.