New complete walking beam furnaces ordered

Thyssenkrupp Steel Europe AG has ordered two new complete walking beam furnaces for steel slabs for the Bruckhausen hot rolling mill #4, located in Duisburg from Danieli Centro Combustion.

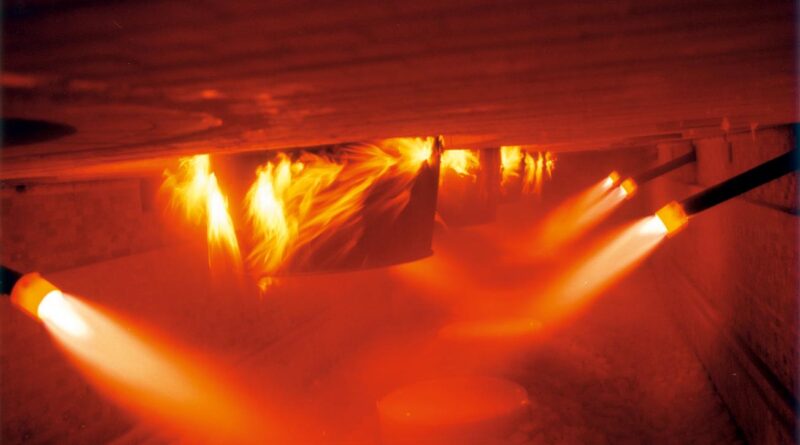

The new walking beam furnace will achieve high production while reducing the energy consumption, NOx emissions and improving slab surface quality. With a capacity of 380 tonnes per hour cold charging, up to 560 tonnes per hour with hot charging, furnace design and performances will be based on energy efficiency maximization, fuel consumption and emission reduction.

The optimization of the combustion system, which is already dimensioned for a possible addition of H2 up to 48% in volume of maximum H2 % about 66%, will lead to furnace efficiency increase and CO2 emission reduction up to about 53 kilograms per tonne by continuous running at maximum productivity.

As part of its Strategy 20-30, the steel producer thyssenkrupp Steel is investing in its capacities to further improve the surface quality of premium sheet steel. These include, for instance, higher-strength multi-phase steels, grades with high surface quality and steels for e-mobility.

One key element of the adaptation of the production network is the division of the casting rolling line in Duisburg-Bruckhausen into a separate new continuous casting line and a separate rolling line.