New, copper rolling mill for Jiangxi Copper Company

China’s extra-large copper cathode producer and supplier of a great variety of copper products, Jiangxi Copper Company, relied on Danieli Fröhling technology and equipment for its plant expansion in Nanchang, Jiangxi, China.

Through this investment, the Chinese producer will add an annual production capacity of approx. 15,000 tons for copper flat products. The additional capacity will be used predominantly for the copper and copper-alloy foil and thin-strip market.

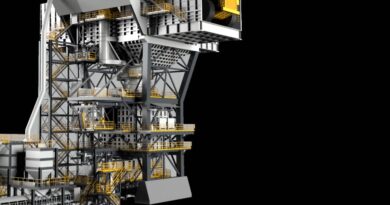

Danieli will provide a new, 20-high reversing mill to roll copper and copper alloys from a maximum entry thickness of 0.8 mm to a minimum finish thickness of 0.03 mm, at a maximum strip width of 450 mm.

The twin-housing type mill will be equipped with the proprietary, Danieli intermediate roll double-bending system for improved strip flatness, and direct hydraulic roll-gap control for high-precision thickness performance. The mills will be capable of using a large range of work roll diameters, from 37 to 80 mm in order to achieve efficient and economic rolling performance.

The core equipment of the new Danieli Fröhling mill will be manufactured, assembled and pre-tested at Danieli HQ workshops. Electrics and automation will feature Danieli Automation advanced solutions such as the HiPAC automation system for real-time, automatic thickness and flatness control.

Danieli advisory services to erection and commissioning activities will complete the supply. The startup of the new copper rolling mill of Jiangxi Copper Company is planned for 2025.