New staves for the rebuild of blast furnace in Taiwan

China Steel Machinery Company (CSMC), a subsidiary of Taiwanese steel producer China Steel Corporation (CSC) has placed an order with Primetals Technologies to supply staves for CSC´s blast furnace 2 at the company´s Kaohsiung plant. The new staves are part of the third rebuild of blast furnace 2. The aim is to extend the furnace´s lifetime by a further 18 years. In future, five out of six blast furnaces operated by CSC and their subsidiary Dragon Steel will operate with equipment from Primetals Technologies. Final delivery is expected for end of June 2020.

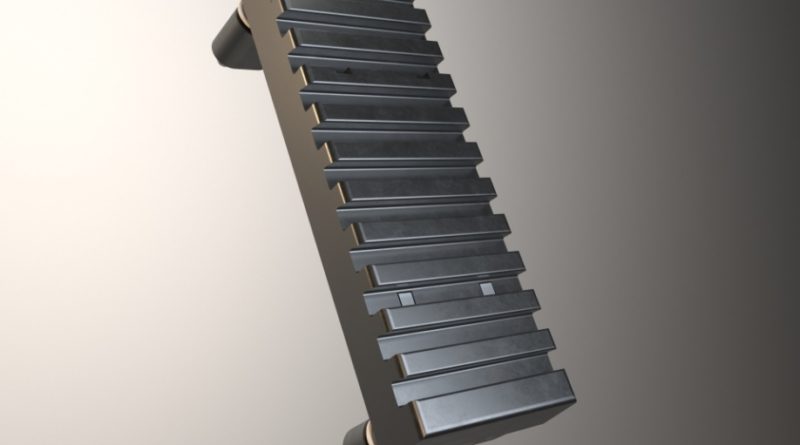

Blast furnace 2 has a hearth diameter of 12 meters and an inner volume of approximately 3,300 cubic meters. Average production is 6,900 metric tons per day. The third rebuild of blast furnace 2 includes a complete shell and cooling system replacement. The cooling system will be a combination of copper and cast-iron staves from hearth to upper stack. Primetals Technologies was contracted to supply 9 rows of cast-iron staves. The installation of the new staves is scheduled to take place during a planned shutdown period in 2020. Blow-in of the rebuilt furnace is expected for early 2021.

CSC is the leading steel producer in Taiwan with an annual production of around 10 million metric tons per year. Around two thirds of the production is for the domestic Taiwanese market, the rest is exported. CSC produces a range of products including plates, bars, wire rods, hot and cold rolled coils, electrogalvanized coils, electrical steel coils, hot-dip galvanized coils, and Ti/Ni-base alloy. The CSC plant in Kaohsiung includes two BOF shops with a total of seven 2-strand slab casters and three 4-strand bloom casters. The slab casters mainly produce carbon and low alloy steels. In addition to supplying BF equipment, Primetals Technologies recently upgraded a continuous slab caster at CSC´s Kaohsiung plant.