Outokumpu Stainless modernises of its Steckel mill in Finland

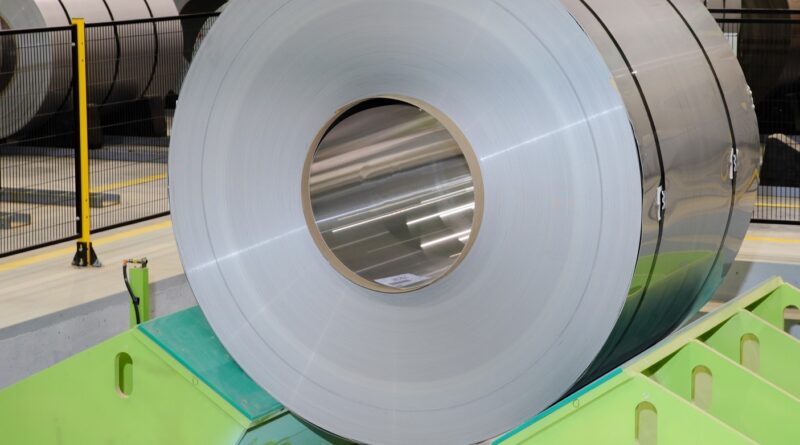

Outokumpu Stainless modernises of its Steckel mill in Finland Outokumpu Stainless (OTK) in Tornio, Finland, granted SMS group the FAC for the successful modernization of its Steckel mill.The modernization secures Outokumpu’s long-term operation of its Steckel mill and reduces both maintenance and downtimes caused by the replaced obsolete equipment.

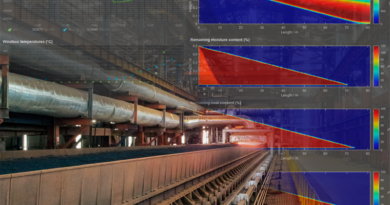

Seppo Lantto, Manager Hot Rolling – Hot Rolling Mills, BA Europe, Tornio Operations summarizes, “We are very satisfied with the implementation and results of the modernization measures. Besides the fact that our plant has been made more future-proof, maintenance efforts and the downtimes caused by the replaced obsolete equipment are both reduced. What really impressed us is the improvement of the availability of the plant.” Outokumpu Stainless has been operating a Steckel mill at its Tornio works in Finland since 1988. Thanks to the long-standing technology partnership with SMS, the Steckel mill has continued to be state of the art. Since 2000, SMS has carried out frequent modernization and extension measures. With this current upgrade, SMS group has renewed the entry and exit sections of the Steckel rolling mill. The measures aimed at making improvements in three plant areas: foundations, pinch roll unit, and side guides. The novel equipment included the implementation of roller tables with side guides and state-of-the-art motors. The new pinch roll unit was fitted with a drive train and motors. The upgraded equipment is mounted on a new steel structure, which replaces the severely damaged concrete blocks. The side guides and pinch roll unit are supplied by hydraulic valve stands. A particular challenge was integrating the new equipment into the plant’s limited available space. This meant quickly developing solutions that had to fit perfectly into the existing installation and meet Outokumpu’s specific requirements.

Thanks to the teams’ excellent performance on a professional and on a personal level, all challenges were overcome.The obsolete equipment was demolished during the four-week main shutdown. This was followed by the foundation work and the new installations, including pipework and cabling, finally resulting in the successful commissioning of the Steckel mill. Once operations were resumed on November 19, 2024, a test phase lasting eight weeks started in which all contractually agreed performance parameters were met.