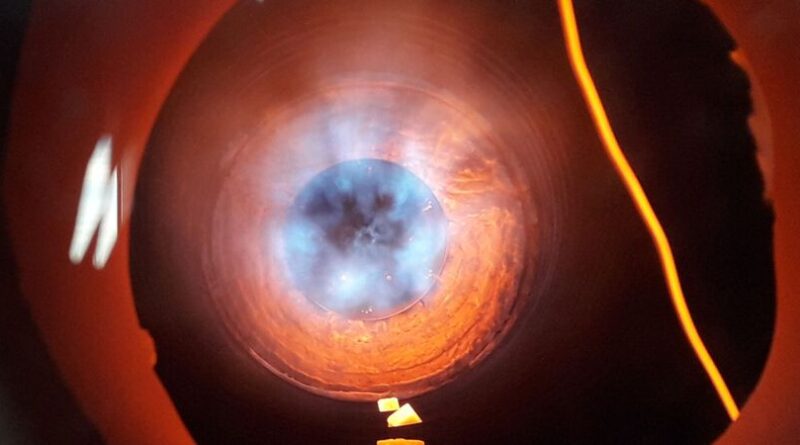

Plasma torch technology to be used in aluminium remelting furnace

Constellium has purchased plasma torch technology from PyroGenesis to be used in an aluminium remelting furnace. The technology will be integrated into a demonstrator furnace at a Constellium casthouse to explore how it could lead to more sustainable high-temperature, industrial heating.

P. Peter Pascali, president and CEO of PyroGenesis said: “Streamlining energy use by electrifying more processes across industrial operations only makes sense when quality and economics remain intact, as is the case with PyroGenesis’ plasma torches.

“Constellium is demonstrating bold leadership in embracing cleaner, more efficient energy pathways. Together, we’re taking a major step toward electrifying an energy-intensive segment of aluminium manufacturing.”

The industrial implementation marks the second phase of the project between the two companies, after an engineering and feasibility study. Ludovic Piquier, chief technical officer of Constellium, added: “We are pleased to take this next step with PyroGenesis to advance the maturity of plasma torch technology for aluminium remelting,

“This collaboration reflects our commitment to decarbonising our operations through innovative, sustainable solutions.”

The current project phase is estimated to be completed by Q1 of 2026.