The scale of the challenge for successful decarbonisation of steel

Wood Mackenzie’s base-case energy transition outlook foresees an average global warming outcome of between 2.2 °C and 2.4 °C by mid-century. Under our AET-1.5 scenario, we assume that the iron and steel industry successfully decarbonises to achieve global net zero emissions by 2050.

This 1.5 °C pathway requires 2050 steel emissions to fall by more than 90% from current levels. This is a staggeringly big ask, given that our base-case steel emissions scenario assumes a decline of just one-third from current levels by 2050. There is an urgent need to act now to decarbonise the iron and steel industry, and business as usual is no longer sustainable.

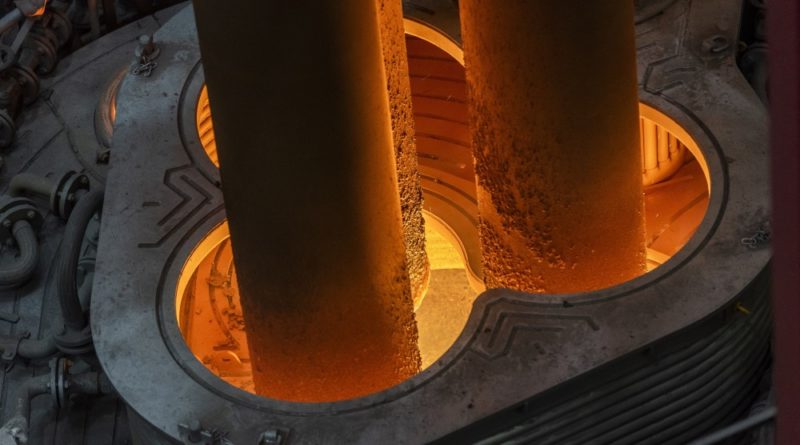

The largest factor in achieving net zero for steel will be switching to electric arc furnaces (EAFs) from the blast furnaces (BF-BOFs) that dominate current production and emit up to four times more carbon. To reduce emissions to the degree required, EAFs will need to be powered by renewable energy, demonstrate greater energy efficiency and elevate the quality of metallics.

Ultimately, the industry must pursue a complete switchover from predominantly hydrocarbon-based energy to renewable power along the value chain, from mining to steelmaking. In parallel, the industry needs to increase its use of less carbon-emissive feedstock, such as green hydrogen and scrap, in steelmaking.

The availability of competitively priced green hydrogen at scale is a must in delivering decarbonisation goals. Commercialising new technologies, such as hydrogen-based direct reduced iron (DRI) and molten oxide electrolysis running on renewable energy, could reduce emissions to zero.

Carbon management through the development and deployment of CCUS will also need to play a key role in offsetting unabated emissions, though this will tail off in the long term as newer technologies that eliminate carbon emissions achieve commercialisation.

Quantifying the scale of this challenge is sobering:

- The industry will require around 50 Mtpa of competitively priced green hydrogen. Commercial viability versus conventional steelmaking routes requires green hydrogen supply at US$2/kg.

- Switching to clean energy will require around 2,000 GW of dedicated renewable generation capacity, equivalent to two-thirds of current global renewable generation capacity.

- High-grade iron ore consumption will have to increase five fold to 750 million tonnes.

- Transitioning to greener feedstock will require a doubling of the global scrap pool from current levels to 1.3 billion tonnes (entailing recovery rates of more than 80%).

- The industry will need to capture and store 470 Mt of carbon to reach its emission target.