Thorium Energy to decarbonize steelmaking with thermal storage technology

The Thorium Energy Alliance will present an outline describing the near-term pathway to 100% decarbonize the steel making process with thermal storage technology being integral to the solution. Thorium Energy Alliance Executive Director Mr John Kutsch will outline the current work being performed to move past feasibility and into production.

The talk will be part of the Association for Iron & Steel Technology’s AISTech 2021 in Nashville on June 29. Mr Kutsch will introduce Caldera Holdings’ Pea Ridge Missouri USA Pure 100% H2 Green Steel Project with Thermal Storage and Thorium Molten Salt Reactors. The Caldera Pure Green Steel Project will show the world that 100% Hydrogen steel is a superior product that will not rely on subsidies and credits to be economical and carbon net-zero.

The critical need to deeply decarbonize the iron and steel industry has garnered much attention over the last few years as more steel is being produced to satisfy the increased demand. Many pathways to reducing or eliminating Greenhouse Gases in iron and steel making have been studied but effective impacts have been few. Capturing excess nuclear capacity via thermal storage will stabilize both nuclear output and intermittent renewables while providing a blueprint for Thorium Molten Salt Reactors design and safety functionality.

Mature technologies make use for industrial process heat and hydrogen at scale production economic thus spurring new advances in traditionally carbon-intensive sectors, steel and iron being a the most promising candidate. Electrolysis systems, DRI systems and Thermal Storage systems are proven and commercially available to produce hydrogen at scale with techno-economics that exceed fossil options for building new steel facilities.

ThREE Consulting LLC has recently applied for DoE FOA funding to generate integrated feasibility studies to validate the techno economic assessment of its Mine to Metal, Green Steel project. The overall goal is to produce superior green steel economically while not relying on carbon-capture credits, subsidies or inflated ‘premium pricing’ for Green Steel. The feasibility studies will demonstrate the economic benefits of utilizing green technologies.

The mine is fully permitted and feasibility production will take less than 18 months. Assuming normal project development timelines and ready investors, the projected steel production start date can be competitive with the state-sponsored SSAB Green Steel project in Sweden.

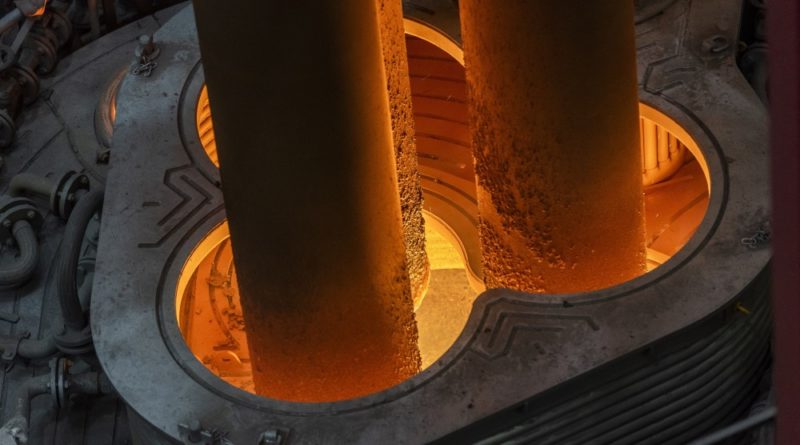

Green steel is produced by replacing coal or natural gas with carbon-free hydrogen gas to convert the iron ore into steel via a process called Direct Reduction of Iron. This technology has been around for decades but only makes sense if the hydrogen can be made at cost-parity with carbon-based options. ThREE Consulting will overcome the existing cost disparity by acquiring underutilized nuclear energy from at-risk producers along with excess renewable capacity to produce economic hydrogen, in conjunction with other systems