Tin miner achieves financial and production records

Alphamin Resources Corp. has provided the following production and EBITDA update for the quarter ended June 2020:

– Tin production up 29% to 2,739 tons versus previous quarter

– AISC per ton of tin sold down 13% to US$10,849 versus previous quarter

– EBITDA of US$12,9 million

– Q3 2020 production guidance of 2,600 – 2,800 tons contained tin

Tin production increased 29% to a quarterly record 2,739 tons and was higher than Alphamin’s previous market guidance due to better than expected tin feed grades.

Plant throughput increased 8% to 91,928 tons from higher underground volumes derived from the new mining method. During the quarter, mined volumes exceeded plant throughput by some 4,000 tons increasing the run-of-mine stockpiles.

The company reports that the processing plant is performing well and various initiatives aimed at achieving consistently higher throughput are underway.

The all-in sustaining cost per ton of payable tin sold reduced by 13% to US$10,849 mainly attributable to increased tin production. Additionally, the previous quarter’s costs were negatively affected by high arsenic penalties and exceptional logistical costs incurred while the national road bridge was under repair.

Production and financial information are disclosed on a 100% basis. Alphamin indirectly owns 80,75% of its operating subsidiary to which the information relates.

EBITDA of US$12,9 million was recorded at an average tin price of US$15,359/t. This represents an EBITDA margin of 32% in a relatively low tin price environment.

EBITDA provides insight into Alphamin’s overall business performance (a combination of cost management and growth) and is the corresponding flow drivers towards the objective of achieving industry-leading returns. EBITDA is profit before net finance expense, income taxes and depreciation, depletion, and amortization.

The Bisie tin mine recorded two lost-time injuries during the past quarter. An employee and a contractor sustained minor injuries during two separate accidents – both will return to work on 10 July 2020.

Production Guidance for the next Quarter

Alphamin expects contained tin production of between 2,600 and 2,8002 tons for the quarter ending

September 2020. The tin price has recently increased to around US$17,000/t compared to a price

achieved of US$15,359/t during this past quarter, which if maintained bodes well for the next

quarter’s EBITDA and cash flow generation.

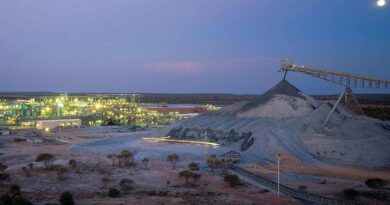

Bisie Tin Project

The Bisie Tin Project is located approximately 60km north-west of Walikale Centre and 180km north-west of Goma, the capital of the North Kivu Province, in eastern Democratic Republic of Congo (DRC).

The project hosts two deposits namely the Mpama North and Mpama South, within the Mining Licence PE13155, which was issued in February 2015.

The project is 84.55% owned by Alphamin Resources through its subsidiary ABM, while the DRC Government owns 5% and the Industrial Development Corporation of South Africa (IDC) owns the remaining 10.45%.

The project is estimated to produce 9,000t a year of tin during its estimated production life of 10.5 years.

The mineralisation at Mpama North site consists a number of narrow veins, blocks or dispersions of cassiterite hosted in a chlorite schist. The tin mineralisation is also strongly associated with copper, introduced in late-stage fractures.

The mineralisation is defined in three distinct vein systems, namely the Hanging Wall, Main and Footwall Veins. The Main vein accounts for 95% of the resources at Mpama North and has thicknesses ranging between 2m and 22m.

The Hanging Wall vein occurs between 4m and 20m above the Main vein, whereas the Footwall vein occurs between 2m and 12m below the Main vein. These two mineralised veins are restricted to the northern and southern areas of the deposit respectively.

The project is estimated to hold probable reserves of 3.04Mt grading 3.76% Sn, containing 114,366t of tin. The indicated resource estimate stands at 3.94Mt grading 3.94%Sn, containing 155,300t of tin, whereas the inferred resource is estimated at 0.84Mt grading 4.64%Sn, containing 38,900t of tin.

The DFS proposes the of the Mpama North pit is mines by proven underground mining methods. The processing plant, with a throughput capacity of 360 kilo tonnes per annum (ktpa), uses conventional gravity separation methods for the recovery of tin.

The process starts with the crushing of the ore, with the coarse material accounting for 75% of the overall crushed material and the fine materials accounting for 25%. The coarse material is recovered using conventional jigs, whereas the fine materials will be recovered using spirals.

The project generates 450 permanent jobs during operations.

The concentrates from the jigs and spirals are milled and further undergo flotation to remove sulphide material. The tin-rich concentrates are then thickened, filtered and conveyed to a smelter for refining.

Alphamin’s unaudited consolidated financial statements and accompanying Management’s Discussion and Analysis for the quarter ended 30 June 2020 are expected to be released on or about 7 August 2020.

FOR MORE INFORMATION, CONTACT:

Maritz Smith

CEO

Alphamin Resources Corp.

Tel: +230 269 4166

E-mail: msmith@alphaminresources.com