Tisco expands its stainless steel product range with 4.3m heavy plate mill

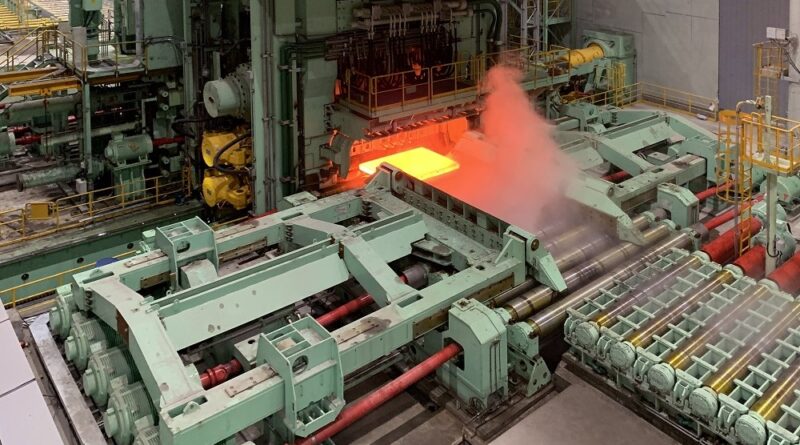

Shanxi Taigang Stainless Steel Co. Ltd. (Tisco), located in Taiyuan, China, has successfully produced the first plate on its new 4.3-meter heavy plate mill supplied by SMS group. It is the most powerful hot rolling mill of its kind ever supplied by SMS. The rolling force of 109 MN in relation to the roll barrel length of 4.3 meters provides the mill a very innovative design and high environmental compatibility. A further distinguishing feature of the mill is the wide range of material it can roll, including carbon steels, quality steels, low-alloyed steels, grades for ship, bridge and pressure vessel construction, weather- and wear-resistant plates, pipe grades according to the API standard, as well as stainless steel and nickel-based materials.

The 4-high rolling stand with attached edger is the central production unit of the heavy plate mill. The vertical edger features combined mechanical/hydraulic roll gap adjustment to achieve extremely tight tolerances. To be able to process even very short slabs, the heavy edging stand is equipped with a newly developed, specially driven support roller table.

The rolling stand is characterized by high rolling forces and a correspondingly high forming capacity. The combination of a very large roll gap opening and the coaxial CVC®plus (Continuously Variable Crown) technology with integrated powerful work roll bending is a new development that allows rolling stock with initial thicknesses of up to 960 millimeters to be processed, providing for an outstandingly wide product range.

SMS achieved the extremely high stiffness factor of the mill by means of various technological design features, such as the use of 2.3-meter backup rolls. Another characteristic feature is the mill’s maintenance-friendly design. Being a market leader in heavy plate rolling technology for many decades, SMS was able to consider comprehensive operating experience and feedback received from customers in the design of the new mill.

Tisco can now produce plates from a wide range of input material, from cast ingots of extreme dimensions to small slabs sizes, to achieve highly flexible and dynamic production in compliance with the tightest geometrical tolerances.

Designed for an annual production capacity of 700,000 tons, the mill can produce plates from 1,550 up to 4,200 millimeters wide within a thickness range from 5 up to 120 millimeters – and more, in the future. Thanks to the new mill, Tisco can provide the market with an extended portfolio of products. In particular, the mill’s capability to process advanced grades, such as stainless and duplex steels, nickel-based alloys and super-austenitic grades, into products that meet the needs of markets, such as infrastructure, chemical, shipbuilding and on- and off-shore wind turbine construction for fossil-free energy production, plays a key role for Tisco.

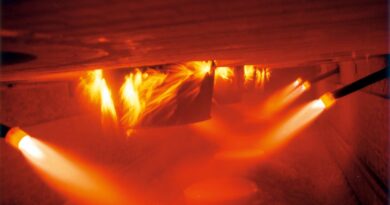

As a matter of fact, environmental compatibility and sustainable production have also been taken into account. The mill stand group is equipped with a newly developed integrated dust extraction system that collects the dust during the rolling process directly at the roll gap. This prevents the release of emissions generated during rolling of e.g. special alloys.

The X-Pact® automation system from SMS provides fully automatic control of the rolling process, while ensuring high mill efficiency. Due to extensive X-Pact® Plug & Work integration testing performed by SMS group and precise planning and intensive cooperation between SMS group and Tisco, commissioning of the mill from the I/O check until rolling of the first plate took only one and a half months. This was two weeks ahead of the original schedule.

Level 1 automation is entirely based on X-Pact® technology. The X-Pact® Vision operating concept takes into account latest ergonomic findings, enabling the operator to operate the system intuitively to ensure optimal process control.

Level 2 process automation includes the technological process models X-Pact® Pass Schedule Calculation PSC®, X-Pact® Profile and Flatness Control PFC® and the higher-level material tracking system.