Two years on, pulping chutes excel at Ekapa

The solid performance of Multotec’s pulping chutes at Ekapa’s diamond treatment operation in Kimberley over the past couple of years has opened the door to quicker and more cost effective fines scrubbing.

According to John Britton, Technical Consultant at Multotec, the two pulping chutes have achieved outstanding results, helping the customer’s facility to cost effectively increase the throughput of its Combined Treatment Plant (CTP).

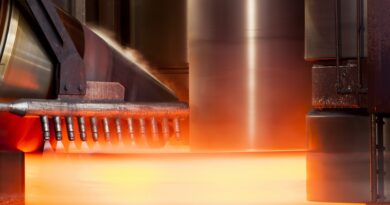

“At our recent two-year inspection of the plant, we found that the wear rate on the ceramic lining of the wave generator was only 20 mm over that 24 month period,” says Britton. “Each chute was processing 380 tph of recrushed kimberlite product with 380 m3 of water, rushing down a 28 degree incline.”

Multotec’s patented wave generators use gravity to create a constant turbulent mixing action in the slurry flow that releases the mud, clay and slime sticking to the kimberlite particles. The chutes are positioned to receive material from the High Pressure Grinding Rolls (HPGR) interparticle tertiary crushing circuit. Multotec’s engineered alumina ceramic tiles give the chutes and wave generators high wear resistance.

“The chutes exceeded our expectations in how well they separated the clay from the kimberlite ore and broke up clay balls in the material stream,” he says. “This has really demonstrated the long term capacity of our design to deliver results with hardly any maintenance or operator intervention.”

He highlights that the chutes are stationery structures which rely on the kinetic energy being created by the inrush of slurry flow over the wave generators. This makes the solution much simpler and less energy-intensive than traditional rotary scrubbers with motors, drives and gearboxes. The chute can also achieve its results much quicker, as the material flow passes through in just three to four seconds.