Shagang Group to produce green ultra-thin steel strip

Ultra-compact and energy-effective Castrip plants were first installed in the U.S.A. and Mexico. In 2018, Shagang Group introduced Castrip technology to China at its plant in Zhangjiagang, Jiangsu Province. Since then, Shagang Group has invested in three further Castrip lines. These new lines were implemented in just 12 months, with the latest becoming operational in June 2024. Shagang Group has already granted the final acceptance certificate (FAC) to Primetals Technologies for the first two lines. In total, Shagang now operates four Castrip lines.

The startup of lines No. 2 and 3 was exceptional in terms of duration and efficiency, thanks to the close and effective collaboration between the project partners, including Primetals Technologies, Shagang Group, and Castrip. Primetals Technologies was responsible for the engineering and supply of core mechanical equipment, technological packages, and automation systems. The entire line is controlled by fully integrated basic (Level 1) and process optimization (Level 2) automation systems, which control all casting and rolling operations.

Lowest Emission Levels in the Entire Industry

Castrip plants are defined by highly flexible ultrathin cast strip (UCS) production at the industry’s lowest energy consumption and emissions levels. Two main factors allow for this remarkable achievement – first, there is no need to reheat the strip, and second, Castrip lines produce strip of close to net shape, which lowers the amount of rolling force needed to meet product requirements. Castrip is therefore an attractive alternative for steel producers looking to decarbonize the production process.

An Uninterrupted Process

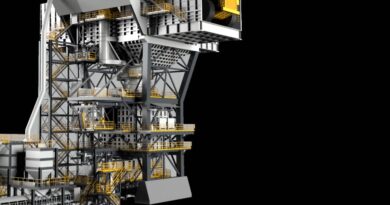

During the Castrip casting process, liquid steel from the meltshop passes through two counter-rotating rolls producing a continuously cast steel strip. The ultra-thin cast strip (UCS) product leaving the caster roll nip then enters an area of the plant with a controlled atmosphere, called the “Hot Box”. This sealed environment reduces the levels of oxidation and prevents excessive scale formation on the newly formed strip. Thanks to the “Hot Box” process, there is no need to descale the strip.

A Castrip line also consists of a single stand hot-strip mill, which reduces strip thickness by 10 to 55 percent. The hot-rolled strip then enters a cooling zone where a controlled decrease in temperature takes place, allowing the strip to meet the desired physical properties. In the next step, the strip is guided towards one of the two coilers, and a rotary drum shear is used to separate the strip, resulting in an uninterrupted process starting from the upstream area and continuing all the way through the Castrip plant.

Increased Hot-Strip Mill Output

Castrip is the ideal solution for steel producers entering the flat steel market, as well as for those looking for additions to their long product portfolio. Castrip also works especially well for creating and producing special steel grades of various types – producers investing in a Castrip line can relieve their hot-strip mill of demanding thin gauges and, in that way, increase the output of the hot mill.

Castrip steel sheet is used, for example, in the construction, purlins, steel framing, steel decking, and racking/storage industries, as well as in lightweighting items for the agriculture sector, automotive parts, and the welded tube industry. Ultra-thin cast strip (UCS) and hot-rolled coils are used as a direct replacement for cold-rolled products and can also be cold-rolled as thin as 0.25 millimeters to expand product ranges.