Hyundai BF gas injection study to improve production and carbon emissions

Recently, Hyundai Steel in Dangjin, South Korea, has placed an order with Primetals Technologies for a blast furnace gas injection study. The study will be executed in two phases.

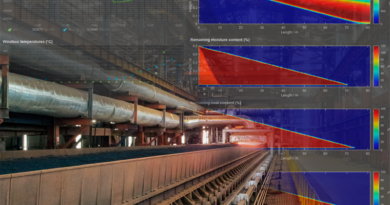

Phase 1 will focus on a process performance study which will evaluate the impact that injecting hydrogen bearing gases into the furnace via the tuyeres will have on production stability, yield, and emission reduction. This phase will also investigate the impact of operating Sequence Impulse Process (SIP) technology on the furnace. SIP technology pulses high-pressure oxygen in a pre-determined sequence to each tuyere; shock waves penetrate deep into the raceway of the blast furnace, combusting the fine char build-up and improving coke permeability. This process enhances gas utilization and improves furnace drainage.

Phase 2 will explore the physical layout options at the plant for each technology, including necessary pipework and associated capital costs.

Supporting the Green Transition

The completed report will enable Hyundai Steel to determine the most environmentally efficient operation of the three blast furnaces at its Dangjin plant. This study is part of Hyundai’s detailed action plan, aiding the development of a long-term technology roadmap that aligns with its goal of achieving carbon neutrality by 2050. By replacing part of the traditional carbonaceous fuels with alternative gas injection, Hyundai Steel aims to reduce the CO2 emissions from the blast furnace. This not only improves the plant’s environmental credentials but is also expected to lower operating costs, reducing the cost per ton of hot metal while maximizing furnace production.

Long-Term Partnership

Whilst this is the first collaboration between Primetals Technologies and Hyundai Steel on blast furnace technologies, the companies have a long-standing partnership. In early 2024, Hyundai turned to Primetals Technologies for heavy plate mill equipment to increase productivity. Prior to this, Hyundai significantly reduced maintenance costs following the implementation of Eco Slide Discs on two of its hot-strip mill down coilers. The companies have also collaborated on the design, installation, and commissioning of a large bar mill and a small bar and wire rod mill which were both completed and received the final acceptance certificate (FAC) in 2019, as well as a continuous bloom caster machine.

A Global Player in Steel ProductionHyundai Steel is one of the world’s leading steel companies, equipped with both blast furnace and electric arc furnace production facilities. Established as Korea’s first steelmaker in 1953, the company has championed sustained success by expanding its blast furnace business alongside its established electric arc furnace operation. Its industry-leading product portfolio includes steel plates, sheets, structural steel, coils, steel casting products, and H-sections, catering to demanding sectors such as automotive, shipbuilding, offshore structures, railways, and construction.