Green Steel Australia to erect green steel rolling mill for long products

Australian company Green Steel Australia awarded Danieli with the order for a new 600,000-tpy rolling mill for the production of rebar in straight lengths from 10 to 50 mm dia, and spooled coils from 8 to 32-mm-dia in customized coils weighing up to 8 tons.

Green Steel Australia relied on Danieli advanced technology and experience of more than 500 long-product rolling mills supplied, to enter the steel business.

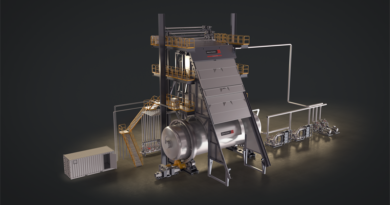

The new rolling mill –which will be installed in New South Wales, near Sydney– will feature the world-first walking-beam reheating furnace with burners operating fully with hydrogen, hence resulting in zero CO2 emissions.

Endless rolling will be performed thanks to a sixth-generation, Danieli-patented horizontal billet welding machine, creating a continuous flow of material to feed the 14 housingless rolling stands, equipped with quick changing system to reduce deadtimes in case of product size change, achieving highest mill utilization factors and material yield.

A six-pass Fast Finishing Block will roll the small sizes and feed both bar line and spooler line, at a maximum speed of 40 m/s.

The supply will include the full technological equipment, mechanical and electrical/automation, as well as overhead cranes, water treatment and compressed air plants, and rollshop.

The high degree of automation and process control will allow Green Steel Australia to minimize the presence of operators in the production line, enhancing safety at the same time.

Danieli CMS, Condition Monitoring System, will help operators with preventive maintenance.