New tin catalyst offers sustainable carbon capture

A breakthrough discovery from researchers at the University of Nottingham and the University of Birmingham is showing how tin can help tackle climate change by reducing carbon dioxide (CO₂). The researchers developed a catalyst made from nano particles of tin supported on a specialized carbon surface that can convert CO₂ into formate, a useful chemical widely used in industries such as pharmaceuticals and manufacturing. This discovery opens up a cleaner, more sustainable method for repurposing CO₂.

CO₂ is the primary contributor to climate change, trapping heat in the Earth’s atmosphere and contributing to rising global temperatures. Reducing CO₂ emissions and finding ways to reuse it is critical for mitigating the impacts of climate change. Traditional methods of CO₂ conversion often rely on hydrogen derived from fossil fuels, making them less sustainable. In contrast, this new approach uses electricity and water, offering a greener and more environmentally friendly solution.

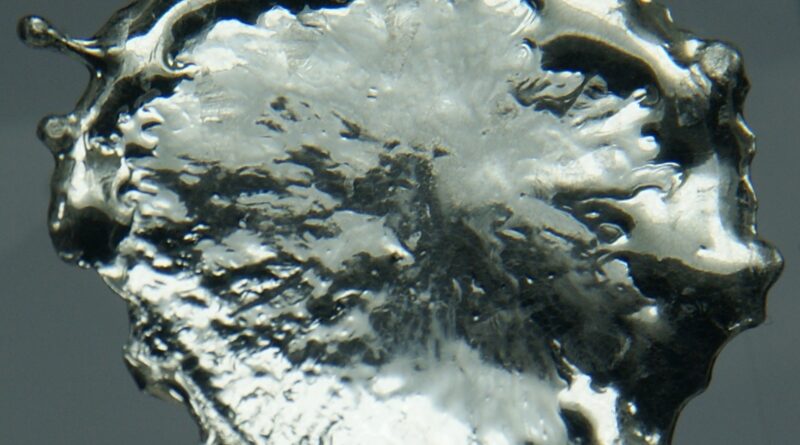

The catalyst developed in this research uses a combination of tin, an abundant and affordable material, and carbon to convert CO₂ into formate under an electric current. This process eliminates the need for fossil fuels, making it a promising technology for sustainable CO₂ reduction. Notably, the performance of the catalyst improves over time, with the CO₂ conversion efficiency increasing by 3.6 times during testing. This improvement is due to the tin particles breaking down into smaller nanoparticles, which increase their effectiveness by enhancing electron transport and maximizing the catalyst’s activity.

This development shows how tin can play a crucial role in reducing CO₂ emissions and transforming them into valuable products. It represents a significant step forward in the pursuit of sustainable solutions to address climate change.