Porous tin foam electrode solves expansion challenges in lithium-ion batteries

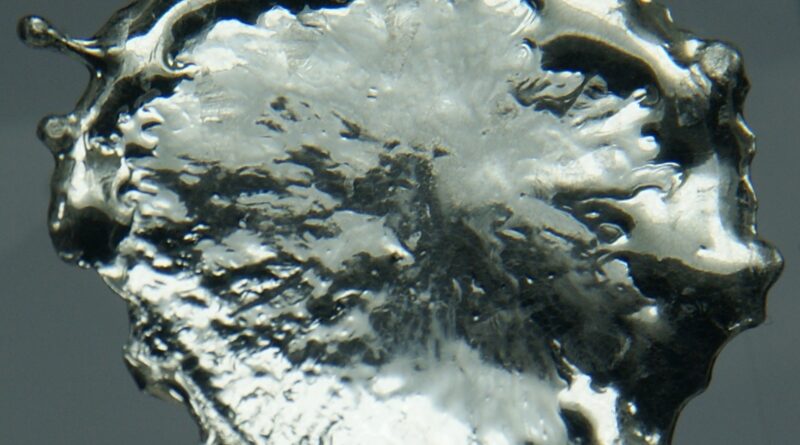

Porous tin foam electrode solves expansion challenges in lithium-ion batteries A breakthrough in lithium-ion battery (LIB) technology has emerged as researchers explore the use of tin as an electrode material to enhance performance.Traditionally, tin electrodes face significant challenges due to severe volume expansion during lithium-ion insertion. However, researchers in Germany have successfully demonstrated that tin foam, as opposed to conventional tin foils, can effectively mitigate these expansion issues, offering a promising solution for improved battery performance.Tin-based electrodes have long been recognized for their high energy density potential in LIBs, with a theoretical capacity of 993 mAh g-1. However, the significant volume expansion experienced by tin during lithiation leads to mechanical stress within the electrode, ultimately shortening the battery’s lifespan.As a result, silicon, which also offers high energy density, is often used in place of tin in lithium-ion batteries, despite facing its own challenges.In the recent study, researchers employed operando X-ray imaging to gain real-time insights into what happens when these tin-based anodes are charging and discharging.The researchers compared two types of tin-based electrodes: a dense tin foil and a novel tin-foam-like structure. The tin-foam electrode, with its porous architecture, was found to be much more resilient during the lithiation and delithiation processes. The pores in the foam acted as a buffer to accommodate the volume expansion, significantly reducing the mechanical stress.The results highlight the potential of tin-based anodes in lithium-ion batteries and paves the way for the development of more robust and scalable tin-based electrodes. Tin anodes are also under development for next-generation sodium-ion batteries.