RUSAL and KUMZ launch aluminium-scandium alloy semi-finished products

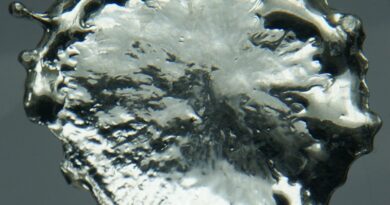

MOSCOW – RUSAL, a leading global aluminium producer, together with KUMZ, has successfully launched the production of various rolled and pressed semi-finished products from an aluminium-magnesium-scandium alloy of grade 1581.

As part of this collaboration, KUMZ organised the commercial production of plates and sheets from ingots, produced by the Krasnoyarsk aluminium smelter in accordance with a specially developed rolling technology. Such semis are in demand amongst Russian customers from the transport-engineering sector, who develop and produce products for the railway and shipbuilding industries.

The alloy of grade 1581, developed by experts of the Institute of Light Metals and Technologies (ILM&T), the RUSAL research and production centre, is an alternative to traditional aluminium alloys. By adding scandium, it was possible to improve its properties by more than 30% compared to AMg5 alloys, while maintaining a high level of corrosion resistance and weldability, which allows the material to be used in welded structures. At the same time, due to the small content of scandium, the cost of this product is significantly reduced relative to existing scandium-containing solutions, which makes it competitive against traditional aluminium solutions.

“Launching the production of this material and its successful entry into the Russian Maritime Shipping Register is the next step in implementing RUSAL’s strategy, to develop and promote innovative scandium-containing products and expand applications of aluminium in high-tech industries,” said Viktor Mann, Chief Technical Officer at RUSAL.

In April, RUSAL launched its new brand of aluminium-scandium solutions, ScAlution. Due to their technological, physical and mechanical properties, these alloys contribute to making vehicles lighter in weight, reducing fuel consumption and air emissions.