SEW-EURODRIVE joins the Mining Indaba community

Johannesburg, South Africa –On its return to the CTICC, the Mining Indaba is looking forward to a reunion like no other and SEW-EURODRIVE is proud to be exhibiting at the highly anticipated industry event.

SEW-EURODRIVE SA is in the process of transforming the local drives and automation segment with its new 26 000 m2 factory in Aeroton, Johannesburg. The new facility houses the company’s head office as well as its massively expanded assembly, warehousing and repair facilities for geared motors and industrial gearboxes, as well as the company’s variable speed drives (VSDs) and servo motors, which will be assembled in a purpose-built clean electronics assembly area.

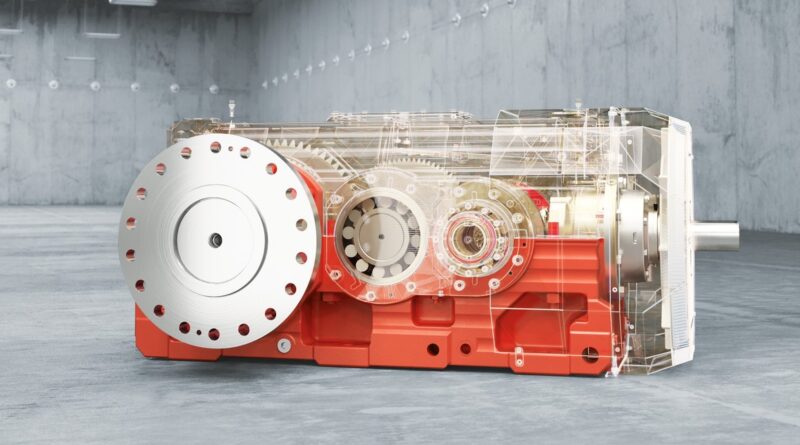

The flagship SEW-EURODRIVE product for the mining industry, the new Generation X.e Series of industrial gear (IG) units will be the first product to be assembled in this new local facility.

On the mill drive side, the use of the new X.e range in girth gear applications has become the global standard where drive reliability and flexibility with respect to speed and control are critical to secure maximum uptime and optimum grinding efficiencies.

For high torque mining applications such as bulk materials handling systems and apron feeder drives on conveying systems, SEW-EURODRIVE’s planetary P-series series IGs can be coupled with primary bevel-helical gear units to offer compact and cost-effective solutions with high thermal ratings.

SEW-EURODRIVE’s new local assembly capability will offer South and Southern African clients massively reduced lead times for replacement drive units and complete drive and power packs, which will result in better support for the local content requirements embedded in the Mining Charter.