Aluminium presses selected to extrude products for demanding applications

Cansan Aluminium awarded Danieli Breda the contract for a 28MN – 8’’ press for extruding automotive profiles. This investment will enable the producer to expand productivity and product portfolio, and follows the one placed with Danieli Breda in 2021 for a 40MN – 10’’ extrusion press.

The latest order awarded by an unnamed Turkish aluminum extruder is for another 40MN–10” short-stroke front-loading extrusion press, dedicated to the production of heavy industrial profiles.

Still in Turkey Danieli Breda has announced the startup and commissioning of a 40MN -10’’ presses for ASEN Metal and the installation of another extrusion press with the same characteristics for PMS Aluminum.

The above presses grant the achievment of the highest product quality, productivity and availability, securing the customers’ competitiveness. To address these challenges, all machines will feature the latest technical solutions developed by Danieli Breda for aluminum extrusion.

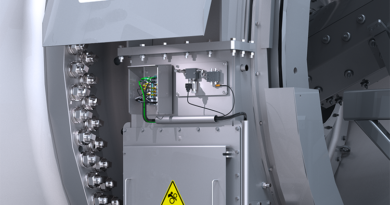

Energy Saving Electrical Drives (ESED 4.0), granting average energy savings of 25-30% and reduced maintenance cost thanks to an optimized and reliable hydraulic configuration.

Extensive use of electric actuators for auxiliary movements, in order to minimize use of hydraulics and simplify maintenance. Advanced automation system with HMI on tablets simplifying operation, maintenance and remote service.

Moreover, to ensure a smooth project development and execution, upon customer request Danieli Breda is also acting as project master, coordinating the activities of all involved subsuppliers for up- and downstream equipment.