Closed-die forging press for aluminium automotive components

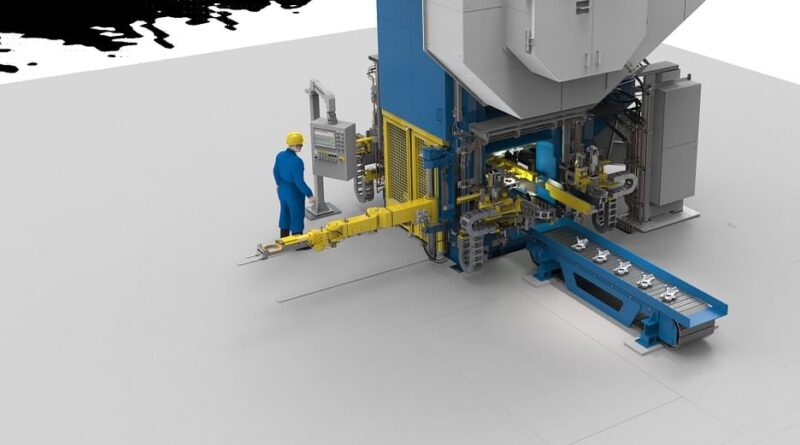

Hirschvogel Automotive Components (Pinghu) Co., Ltd., a leading manufacturer of automotive parts and components in China, has contracted SMS group to supply a fully automated MP 3150 closed-die forging press.

At the Pinghu location near Shanghai, the press will forge aluminium chassis components with high dimensional accuracy at an exceptionally short cycle time. With this investment Hirschvogel accompanies the market development towards light-weight electric vehicles.

The closed-die forging press will be equipped with a fully automated walking beam system with servo drive for each axis to ensure a perfectly harmonized and smooth sequence of movements. Integrated sensors will permanently monitor the ram position to ensure trouble-free operation.

An electro-hydraulic combined clutch and brake unit will be installed for precise switching actions and require just little maintenance. Press parameters will be monitored by an integrated process control system.

Commissioning of the fully automated forging press line is scheduled for the second quarter of 2022.