Compact infrared thermometers for spot or thermal images

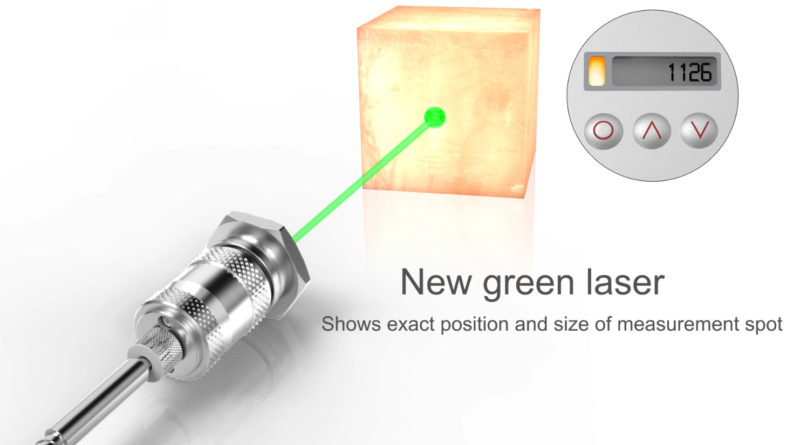

INSTROTECH, local representative of Optris – leading manufacturers of non-contact temperature measurement devices – has launched CTratio, offering many improved parameters and new features such as the low bottom temperature of 275 °C, a maximum ambient temperature of up to 315 °C without cooling, and a green sighting laser.

Spot Measurement or thermal imaging?

A point measuring infrared thermometer should be used if users know where the critical point or the area to be measured is positioned within the application. The size of the measuring object is important to define which lens is necessary. It is therefore possible to monitor the accurate temperature and optimize processes – if necessary – before quality problems arise.

Infrared cameras should be used in cases where more than one critical area exists or the area cannot be clearly defined. Critical areas can be localized by the camera through the demonstration of thermal images. The areas can then be permanently monitored by one or multiple fixed infrared thermometers.

Which object surface?

The condition of the object surface defines the measurement device and wavelength to be used for the application. The emissivity Ɛ occupies a central position. The choice of the right device is of great importance especially for metals, where the emissivity depends on the temperature and wave length. Optris is able to offer appropriate measurement devices for most applications throughout a wide product range. The following explanation helps to find the right wavelength for the application:

(TEMPERATURE DIAGRAM 1)

Which temperature range?

The temperature is another factor to decide on. The range should cover all relevant temperatures of the application. The measurement range of the devices is between –50 °C and 3000 °C.

(TEMPERATURE DIAGRAM 2)

Caption: Display of temperature over wavelength for the devices of the compact and the high performance series

Short wavelengths reduce measurement errors on surfaces with low, unknown or changing emissivity. This occurs mostly with metals. The diagram above shows the measurement errors across different wavelengths if the emissivity is wrongly adjusted by 10 percent.

Which process velocity?

To achieve accurate temperature measurements, it is important to know how fast measuring objects are moving in front of the sensor, or how fast they change temperature. Our fastest infrared thermometer captures changes within 1 ms.

(FAST TEMPERATURE DIAGRAM 3)

Caption: Display of fast temperature changes over a period of time.

Integration of sensors?

Optris temperature sensors can be installed as part of the process with mounting brackets or flanges. Depending on the device, Optris offers different analog and digital interfaces for data evaluation such as triggering, alerting or saving of data.

Analog Interfaces:

0 – 20 mA, 4 – 20 mA, 0 – 5 V, 0 – 10 V,

Thermocouple (type J, type K)

Digital Interfaces:

USB, RS232, RS485, Relay, Profibus DP, CAN Bus,

Ethernet

(DIGITAL INTERFACES DIAGRAM 4)

Contact INSTROTECH for more information on Optris CTratio for spot measurement or thermal images, on 010 595 1831 or sales@instrotech.co.za

VIDEO LINK: https://www.optris.global/tutorial-ctratio