EAF furnace designed to handle scrap of varied composition and quality

Chinese steel producer Wuzhou Yongda Iron and Steel Co., has issued the final acceptance certificate (FAC) for an EAF Quantum electric arc furnace and twin ladle furnace supplied by Primetals Technologies for a greenfield project of in Wuzhou city, in Guangxi Zhuang Autonomous Region.

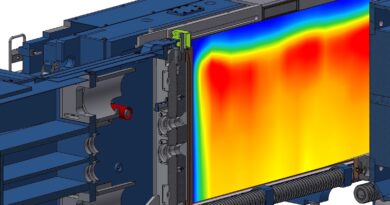

The EAF Quantum furnace is designed to handle scrap steel of very varied composition and quality. The electrical energy requirement of the electric arc furnace is extremely low because the scrap is preheated. This reduces both the operating costs and the CO2 emissions. The twin ladle furnace sets the desired steel grades and the correct casting temperature.

Wuzhou Yongda is privately owned and located in Wuzhou near Guilin city in Guangxi Zhuang Autonomous Region in Southern China. The company produces steel rods, coiled rebar and coiled wire and with the new plants increased its annual production for the construction industry. Primetals Technologies supplied the complete mechanical and electrical process equipment for the new EAF Quantum electric arc furnace and the twin ladle furnace. The balance of plant equipment and services will be provided by a local design institute.

The EAF Quantum and the twin ladle furnace are part of a greenfield project for the production of carbon steels. For the EAF Quantum electric arc furnace and the twin ladle furnace, Primetals Technologies supplied the complete mechanical and electrical process equipment and the automation technology.

This included the automated scrap yard management, the automated charging process, automation of the oxygen injection and sand refilling, as well as the Level 2 automation which makes the plant ready for Industry 4.0. A basic data package for dedusting equipment was also part of the project.

The EAF Quantum developed by Primetals Technologies combines proven elements of shaft furnace technology with an innovative scrap charging process, an efficient preheating system, a new tilting concept for the lower shell, and an optimized tapping system.

This all adds up to very short melting cycles. The electricity consumption is considerably lower than that of a conventional electric arc furnace. Together with the lower consumption of electrodes and oxygen, this gives an overall advantage in the specific conversion cost of around 20 percent.

In comparison to conventional electric arc furnaces, total CO2 emissions can also be reduced by up to 30 percent per metric ton of crude steel. An integrated dedusting system with modern automatic off gas control fulfills all environmental requirements.