Intelligent instruments for optimizing mining operations

Metso Outotec has grouped its portfolio of intelligent instruments under the Sense series. The portfolio is designed to solve specific process challenges and enable optimization for minerals and hydrometallurgical processes. The market’s most comprehensive portfolio of intelligent instruments is part of Metso Outotec’s Planet Positive offering. Covering the entire flowsheet, Sense series instruments are suited for both new and existing operations.

“Metso Outotec Sense series includes specialized instruments that provide data for analytics and a better understanding of processes. They utilize the latest technologies, such as artificial intelligence (AI) and neural networks for extra insight. These additional tools for process problem solving and data mining can significantly help improve production within customer operations,” explains Veli-Matti Järvinen, Vice President, Automation product group at Metso Outotec.

The latest additions to the portfolio bring improved value

- FrothSense+ takes flotation optimization to the next level with the latest technology and capabilities. It has completely new and redesigned software and hardware. It includes the best features from two legacy systems, FrothSense™ and VisioFroth™, and adds new capabilities such as froth height measurement, history analysis and artificial intelligence with deep learning algorithms to detect flotation properties.

- The new RockSense product family will take comminution optimization to the next level with better knowledge of particle size distribution (PSD) on the belt. RockSense consists of a renewed, two-level offering: RockSense 3D and RockSense 2D, formerly known as VisioRock™. They enable online, continuous on-belt coarse particle size distribution. RockSense 3D also adds new capabilities with artificial intelligence and deep learning algorithms to detect oversized lumps and foreign objects, for example.

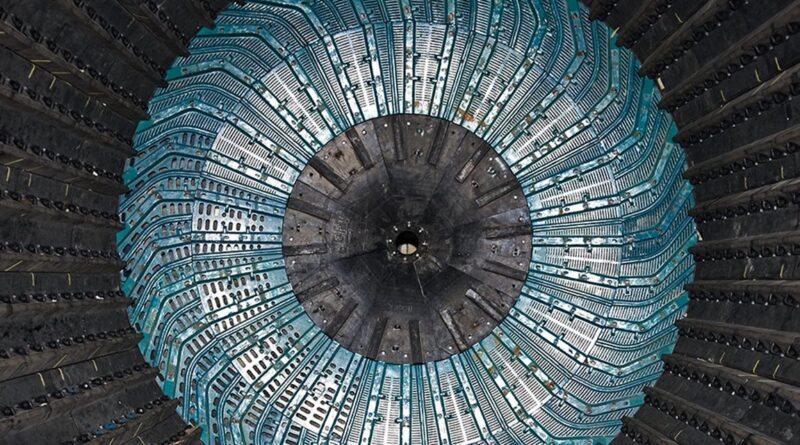

- Metso Outotec MillSense provides online volumetric charge analysis by direct measurement of charge position. It is now available, together with SmartEar, as a bundle. SmartEar uses sound to give an additional measurement of charge impacts and liner wear. The bundle fuses acoustic, vibration and force sensor information for improved online analytics of mill operations. This enables new ways of optimizing grinding performance.