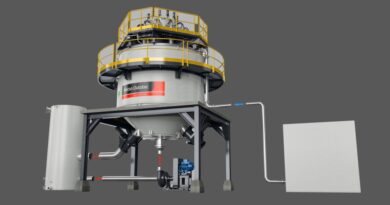

Mine system for complete end-to-end conveyor solutions

Metso Outotec has received an order for a heavy-duty mine conveyor system in South America. The delivery consists of high reliability overland conveyors, including a 2-km single flight conveyor. Equipment provided in this package runs at speeds of up to 6 m/s with a delivery capacity of over 9,000 t/h. The order value is approximately EUR 10 million and it has been booked in Minerals’ Q1/2021 orders received.

“Metso Outotec’s full range of overland conveyor solutions provides economic and reliable material transportation for both open-pit and underground operations at the lowest total cost of ownership. Metso Outotec’s patented Energy Saving Idlers (ESI) bring important power savings to long-distance conveyors, reduced belt tension, and extended rollers life, enabling a reduced maintenance cost over the equipment life and a more sustainable operation,” says Alexandre Martins, Business Manager, Crushing and Conveying Systems business line at Metso Outotec.

The Metso Outotec conveyor offering covers complete end-to-end conveyor solutions. This includes concept studies and definitions for all types of terrains and route types with horizontal and vertical curves. In addition, the offering also includes post-installation services and maintenance, including a full range of accessories, belts, and components for different types of applications. Metso Outotec conveyors are built from high-quality materials and are based on extensive testing and more than 100 years of engineering experience.