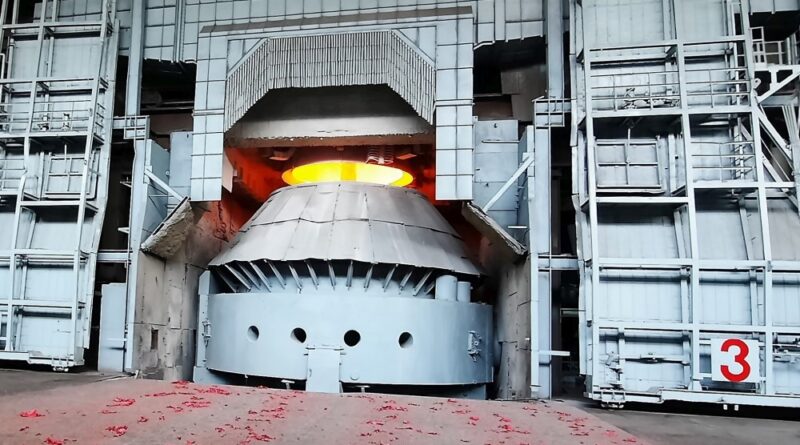

New KOBM converter shortens blowing process and improves steel purity

A KOBM converter, upgraded from a former BOF converter by Primetals Technologies, has started up in the steel plant of HBIS Group Handan Iron and Steel in Handan, China. Compared to a BOF converter, the combined blowing from top and bottom in a KOBM converter results in a better bath mixing and metallurgical reactions are closer to the equilibrium.

In addition, lime injection ensures fast slag formation and excellent process and slopping control. Therefore, this process is expected to shorten the blowing process, to lower the carbon-oxygen equilibrium of the steel at tapping, improve the yield by lowering slag amount and iron oxide content in the slag, and to produce cleaner steel with minimum inclusions and impurities.

The improved steel quality especially fits requirements from the automotive industry. Furthermore, the new converter has the potential to save ladle additions during tapping as well as costs for lime additions.

Primetals Technologies was responsible for engineering, manufacturing and supply of equipment, including a new process control system. In addition, services for erection, start-up and commissioning were provided. Training on site took place during commissioning, under strict regulations.

HBIS Group awarded this project based on Primetals Technologies’ large number of installed KOBM converters and the combined plant engineering, metallurgical, process-specific and automation know-how with respect to this sophisticated steelmaking technology.

HBIS Group, among Fortune 500, has been cooperating with Primetals Technologies for more than 14 years for the building of new plants, the upgrade and modernization of existing plants, the lifecycle management as well as the automation and digitalization of its steel factories.