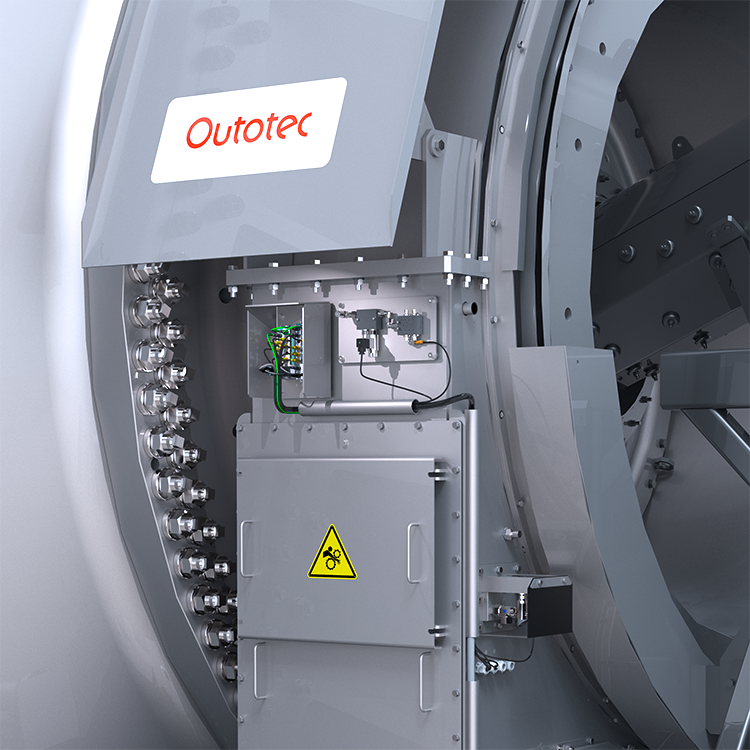

Safe, reliable control solution for increasing grinding mill availability

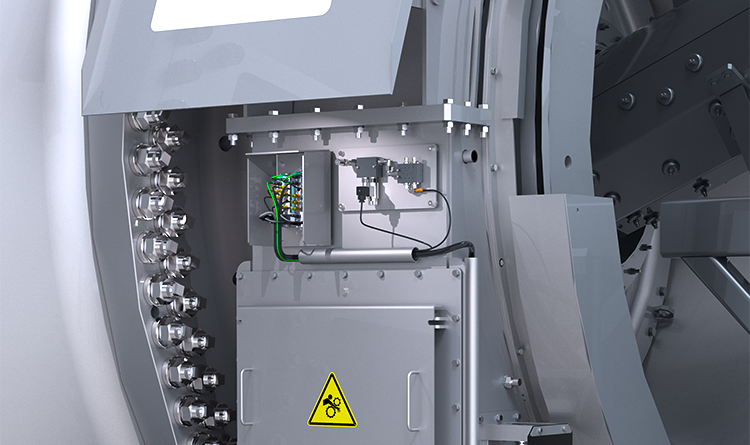

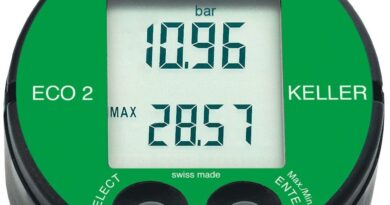

The Outotec® Mill Control System provides all control functions required for the safe operation of grinding mills and their associated lubrication systems, as well as continuously monitoring the equipment’s condition. The system allows for advanced condition monitoring strategies, including remote expert support, to ensure maximum mill availability.

The modular solution proactively detects anomalies, using diagnostic data from IO-Link instruments to determine instrument health and detect installation problems before they cause downtime. Remote connectivity hardware is included as standard, enabling connection to Outotec’s Connected Services for remote diagnostics and support. Plant owners can also take advantage of Outotec’s cloud-based Asset Analytics service to gain valuable insights over the condition and performance of their assets.

The system uses standard hardware and software components that are common across Outotec product lines for improved availability of support resources and spare parts, and meets all relevant EU safety directives and other key international safety standards.

IO-Link technology enables digitalization and smart instruments by allowing for extended diagnosis of sensors and actuators, and the use of IO-Link instruments contributes to time and cost savings as the single interface means that fewer I/O spares are required.

Outotec Mill Control System – key benefits

- Increased mill availability

- Significantly reduced commissioning time and cost

- Shorter engineering lead time and superior installation quality thanks to simplified wiring and termination design as well as standardized software and hardware modules

- Reduced project risks with complete solution delivery under one contract

- Ensured compliance and reduced risk with state-of-the-art safety-rated hardware