Tin smelter relocated, producing at 90% capacity

Tin recovered from an end-February stumble in the base metals complex. The price now sits at nearly US$ 26,000/tonne. Three month prices had previously peaked at US$ 27,500/tonne on 25 February, before falling below US$ 23,000/tonne at the beginning of March.

Strong fundamentals continue to support high prices. Despite the backwardation flaring back out to around US$ 3,000/tonne, little metal has entered the LME. Premiums are reportedly at record highs, with little metal available on spot deals.

Customers are having to over-order metal, if possible, to ensure stocks are available should deliveries be delayed. Heavier-than-normal seasonal rains are impacting both Indonesian and Brazilian mining, constraining metal output.

In 2006, the Chinese government announced environmental reforms that forced smelters within 1 km of residential areas to be relocated. Located in the centre of Gejiu City, Yunnan, the smelter was deemed too close to residential areas. In 2013, Yunnan Tin began the process of relocating its main smelting facility.

YTC chose the Mengzi Economic Development Zone as the new home for its tin smelting operations. The company already has extensive operations in the area, having invested in copper and lead smelters there in 2011.

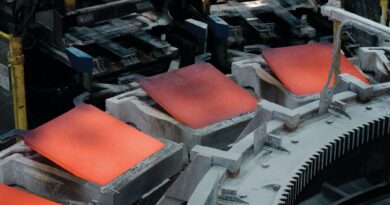

Commissioning of the new smelter, which began on 26 November 2020, has now been completed according to the press release.

The company has reportedly tested all sub-sections of the smelting project, and completed a test run of the complete process. Refined tin output, as well as economic and technical factors, have steadily improved over the process.

Currently, the smelter is running at around 90% of the designed capacity. YTC estimates that some 11,800 tonnes were produced between January and February.

YTC’s new smelter is similar to the previous iteration in Gejiu City. The Ausmelt furnace has a design capacity of 70,000 tonnes of refined tin per year, and can be operated with a high degree of automation.

Experts expect that output at the new smelter to stablise to design capacity levels in the coming months. Once this is achieved, YTC starts to begin decommissioning the old smelter.