Variable area flowmeter for process monitoring and control

Whether for gases or liquids, INSTROTECH has Kobold’s KDS flowmeter, which performs process monitoring and control tasks reliably. Via a magnetic tracking system, the float position is transmitted to a corresponding pointer and optionally to an analogue output.

The fluid flows from bottom to top through the meter tube of the flowmeter. The float is lifted until an annular gap between the measuring cone and the float is produced which corresponds to the flow. The forces acting on the float are in equilibrium. The height of the float resulting from the flow rate is transmitted by the permanent magnet in the float through the magnetic tracking system in a rotation to the pointer axis of the analogue indicator unit.

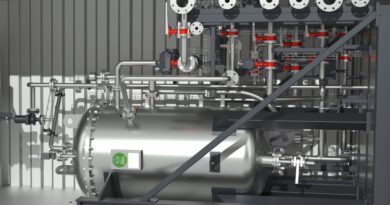

The variable-area flowmeter comprises a stainless steel device with an integrated conical stainless steel measuring tube and a vertically movable float. The KDS-K/C model has a built-in valve for setting the flow rate. The robust Kobold KDS flowmeter with its low wear rate is widely used in the chemical industry as well as in medical and laboratory engineering. It is used for measuring mass and volume flow rates, or for dosing applications, and is available with additional electrical equipment for process monitoring and control. The KDS meter is also suitable for flow measurement of liquid or gaseous products in pipes. It shows the current flow rate in volume or mass per unit in time.