Why is now time for Lithium mining?

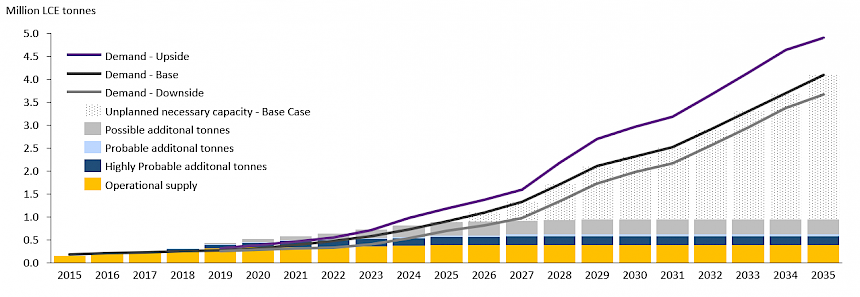

The global energy storage revolution is generating high demand for new sources of lithium (Li) with analysts forecasting significant demand increases for lithium carbonate and lithium hydroxide used in the production of lithium-ion batteries.

Electric vehicles (EV) and grid energy storage are becoming a huge demand driver for lithium-ion batteries and the need for more lithium production. Battery giants and major automakers world-wide are scaling up battery production with mega-factories and are actively acquiring lithium through off-take and joint-venture agreements.

Lithium Demand Forecast by Benchmark Minerals

Increasing battery production is driving demand for increasing lithium production with the completion of a US$5 billion large-scale lithium-ion battery gigafactory near Sparks, Nevada. Supply of lithium for the Tesla & Panasonic battery gigafactory should come from Nevada due to tax incentives received of US$1.3 billion over 10 years.

There are over 150 large-scale battery mega-factories world-wide in the planned production pipeline to 2028 (Benchmark Minerals) and are based on lithium-ion batteries becoming an all purpose energy storage unit that are highly scalable.

Mining companies already producing lithium are attempting to increase their production through acquisition and joint-venture agreements. Rockwood Holdings was purchased by Albemarle for US$6.2 billion. The purchase included the Silver Peak lithium mine located in Clayton Valley, Nevada.

With the United States producing less than 2% of the world’s lithium, the U.S. Government has designated Lithium (Li) as a “Critical Mineral” of strategic importance to the Nation’s economic and national security. The policy of the U.S. Government is to reduce the Nation’s vulnerability to disruptions in the supply chain of critical minerals.

The “Critical Mineral” designation favors domestic sources of lithium that offer a secure, reliable source of supply. The size of the resource makes Cypress’ Clayton Valley Project a premier source that has the potential to significantly impact the supply of lithium that is produced in the United States.

LITHIUM USES

The most important use of lithium is in rechargeable batteries for electric vehicles, home, business and grid storage systems, mobile phones, laptops and other consumer electronics. Lithium is also used in some non-rechargeable batteries for things like heart pacemakers, toys and clocks.

There is a very good reason why lithium in batteries has become the metal of choice. Lithium is the most reactive metal known, also the lightest, with an atomic number of 3. Used in batteries, lithium provides much better energy per volume ratio or energy density than an ordinary alkaline battery or other common rechargeable battery such as a nickel-metal hydride.

This is in part because lithium is the third-smallest element after hydrogen and helium, and thus a lithium ion can carry a positive charge in a very small amount of space. Lithium-ion batteries can be recharged by running the anode and cathode reactions in reverse and the ability to be recharged many times over without much loss of capacity is another major advantage of the lithium-ion battery.

Lithium metal (Li) is also made into alloys with aluminium and magnesium, improving their strength and making them lighter. A magnesium-lithium alloy is used for armour plating. Aluminium-lithium alloys are used in aircraft, bicycle frames and high-speed trains.

Lithium oxide is used in special glasses and glass ceramics. Lithium chloride is one of the most hygroscopic materials known, and is used in air conditioning and industrial drying systems (as is lithium bromide).

Lithium stearate is used as an all-purpose and high-temperature lubricant. Lithium carbonate is used in drugs to treat manic depression, although its action on the brain is still not fully understood. Lithium hydride is used as a means of storing hydrogen for use as a fuel.