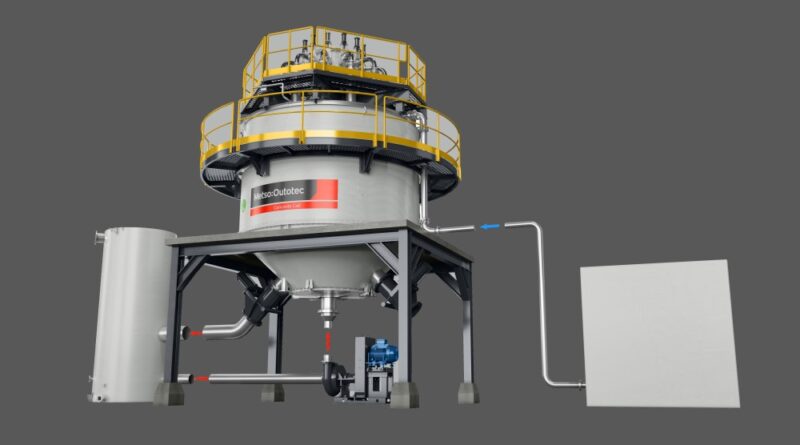

Concorde Cell flotation technology for fine/ultra-fine particle recovery

Metso Outotec is launching groundbreaking Concorde Cell flotation technology for efficient fine and ultra-fine particle recovery. This innovative technology sets a new benchmark in high-intensity pneumatic flotation, reducing plant operation costs and contributing to sustainability of operations through minimized energy and water consumption per tons of metal produced.

The patented Metso Outotec Concorde Cell technology is the first fine and ultra-fine flotation solution for more finely disseminated and complex orebodies that have previously been inaccessible.

The Concorde Cell forced-air Blast Tubes treat 100% of fresh feed combined with tailings recycling for improved performance, allowing finer grinding to get extra liberation without the risk of valuable particles lost into tailings.

Combining the well-proven TankCell technology with Concorde Cells is a low-risk and high-benefit approach for minerals processing flowsheets. The cell produces very high shear and extremely fine bubbles, which increases recovery in particles under 20 microns.

The offering also includes Blast Tube retrofit kits for upgrading the metallurgical performance of self-aspirated pneumatic flotation cells to the Concorde Cell technology. In addition, Metso Outotec can provide a complete slurry handling package for the Concorde Cell, including pumps, spare parts, as well as optimization and maintenance services.