COVID-19 blamed for Minsur’s tin production fall

Production at Minsur’s Peruvian operations fell in the first quarter following smelter maintenance and COVID preventative measures.

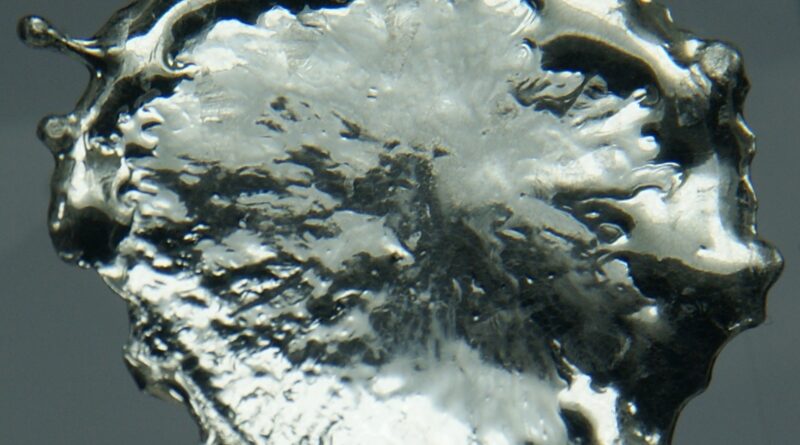

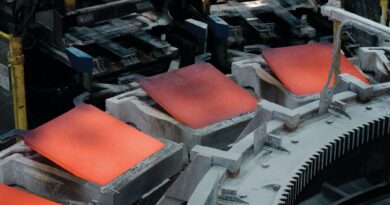

Minsur is one of the world’s largest tin producers and operates the San Rafael tin mine and B2 tailings reprocessing project in Peru, along with the Pisco smelter.

In the first quarter of 2022, the grade of processed material rose to 2.18% Sn, compared to 2.00% Sn last year and 2.06% Sn last quarter. Head grades at both San Rafael and B2 improved to raise the average.

However, mined tin production fell compared to a year earlier. In January 2022, COVID cases in Peru rose rapidly to a peak of nearly 100,000 daily cases. As a result, Minsur operated its processing plant at lower capacity in order to prevent the spread of cases amongst its workers. Less material was therefore fed through the processing plant (-19% QoQ, -8% YoY), resulting in a combined 6,818 tonnes of tin (+1% QoQ, +6% YoY).

Despite more tin being produced at the processing plant, refined tin output at Pisco fell in the first quarter. The smelter produced some 5,903 tonnes of metal, down 7% YoY and 11% QoQ. Annual smelter at the maintenance was brought forward a month (into March), resulting in the lower output.

Minsur’s costs of production rose in Q1. Cash costs averaged US$ 10,999/tonne, up 11% QoQ and 33% YoY. Higher costs were primarily caused by the lower throughput at the processing plant, although higher input costs were also a factor.

The company also noted that exploration activities resumed during the quarter after they were postponed last year.

COVID cases in Peru fell rapidly following its January peak, and the weekly average now sits at under 300 cases. As a result, we see Minsur’s Q2 refined tin output rising significantly. The company is now sitting on stockpile of processed concentrate, which it can smelt during the quarter, while processing capacity is likely to return to normal.