Electric cars and Formula E powered by nickel

During the recent ‘battery day’ event held by Tesla, Musk called on resources companies to increase their nickel production, to meet the anticipated demand being created by strong growth in battery production for both electric vehicles and energy storage systems.

“Wherever you are in the world, please mine more nickel and don’t wait for nickel to go back to some high point that you experienced some five years ago. Go for efficiency and environmentally-friendly nickel mining at high volume,” Musk told the battery day event.

“Tesla will give you a giant contract for a long period of time if you mine nickel efficiently and in an environmentally sensitive way,” Musk added. This isn’t nickel-and-dime stuff, we’re talking big money and bigger stakes.

Musk told the event that Tesla was aiming to improve its battery technologies setting targets to reduce manufacturing costs by 56 per cent, and deliver an increase in electric vehicle range of 54 per cent.

Nickel in electric car batteries is more important than lithium at this stage and a Tesla Model 3 contains 30kg of it. Elon Musk has pointed out that lithium-ion battery isn’t quite correct as the quantum of lithium is small, 2% in a lithium-ion cell.

He and his colleagues at Tesla prefer the term nickel-graphite (battery) as the main constituent in the battery cell is nickel. Principally the cathode is nickel and the anode is graphite with silicon oxide. As Mr. Musk says, there is “a little bit of lithium in there, but it’s like the salt on the salad.”

According to UK energy consultancy Wood Mackenzie, nickel consumption in electric vehicle batteries is expected to grow by over 60% up to 2025. The problem however is supply, as little capacity has been added in the past few years; one big-listed mining company intends to change that.

Speaking at the Diggers and Dealers forum in Kalgoorlie on Tuesday, asset president for BHP’s Nickle West subsidiary, Eduard Haegel, said calls by Tesla’s Elon Musk for more nickel production highlighted the scale of opportunity being created by the clean energy sector for materials, but stopped short of confirming that BHP had finalised a nickel supply deal with Tesla.

“Nickel West is well positioned to benefit from this anticipated growth. Last year, we sold around 70 per cent of our nickel to battery manufacturers around the world, making BHP one of the world’s leading battery metal suppliers.”

Asset president for BHP’s Nickle West subsidiary, Eduard Haegel, said calls by Tesla’s Elon Musk for more nickel production highlighted the scale of opportunity being created by the clean energy sector for materials, but stopped short of confirming that BHP had finalised a nickel supply deal with Tesla.

“Nickel West is well positioned to benefit from this anticipated growth. Last year, we sold around 70 per cent of our nickel to battery manufacturers around the world, making BHP one of the world’s leading battery metal suppliers,” said Haegel.

Other Australian miners have sought to expand their involvement in the production of raw materials for the clean energy sector, including an expansion by Rio Tinto of its production of copper and lithium, and Australian lithium producer Piedmont Lithium, has already secured a deal to supply Tesla.

Most nickel production is intended for stainless steel. Maraging steel for example is super strong whilst remaining ductile and with an 18% nickel content has the impact-fatigue strength required for aircraft landing gear.

About 3% of the world’s nickel supply is used in batteries, but this is rising fast. Nobody has yet developed a technology that matches nickel for its density – the power to weight ratio – that is critical in cost-effectively moving EVs.

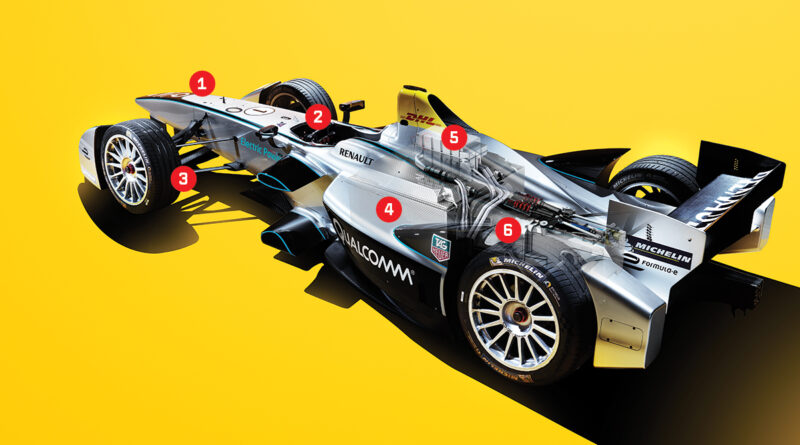

Formula E racing is pushing the boundaries of battery power and may even displace traditional Formula 1 in the future. English company Williams was commissioned to build the first batteries but now another English technology firm McLaren has taken the lead.

The challenge has been significant. The Formula E battery has to propel cars to speeds of up to 225kph, yet still be practical in terms of safety, aerodynamics, range and recharging times.

The chemistry inside McLaren’s Formula E batteries is a technical secret but the supposition is that McLaren is using a nickel-heavy design for enhanced energy density, with 8-1-1 chemistry, using eight parts nickel for every one-part cobalt and manganese.

This future-fronting commodity will be in accelerating demand, with pricing likely to stimulate further exploration and production. What is interesting too is that mining and smelting is possible in an environmentally clean manner. And with Elon Musk leading the clean charge, miners will be incentivised to follow.