Gears designed to be more robust, reliable, efficient, easier to maintain

The latest generation SEW-EURODRIVE industrial gear units in the X.e series have been purposefully designed with a host of new improvements to be more robust, reliable, efficient and easier to maintain.

This modular series is designed to be custom-built based on the exact needs specified by clients, most notably by significantly increasing the number of possible torque/speed combinations and fine-size graduations. A large number of additional modular features and options, such as motor adapters, backstops, various sealing and shaft systems and many more, also add to ease of use and reliability of X.e Series systems.

Key applications across Africa include:

- Conveyor drives, which are often required to operate in extremely dusty and very hot or cold conditions. Due to new thermally optimised housings, particularly in the X180 and above sizes, along with the contact-free Taconite sealing system design, these drives offer excellent reliability under these conditions.

- For hoists, which often feature the rope drum and the motor on the same side of a parallel-shaft unit, the X.e hoist series offers an optimised choice of gear unit sizes, reduced gear unit weight and sufficient centre distances.

- For bucket elevators required to lift bulk materials, the drive needs to be operated at low speed during maintenance. X.e series bucket elevator drives are equipped with a directly mounted auxiliary drive to perform this function while the main motor is switched off.

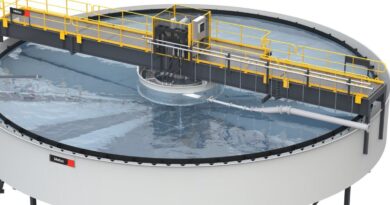

- For agitator and aerator drives, X.e agitator gear units in the 22 to 90 kNm size range have extended bearing distances to absorb high radial and axial forces. In addition, due to their thermally optimised housings, these units can be used without external cooling, even in high performance agitation applications.

Perry also cites the use of the new X.e range in girth gear applications, where the new generation units have become the global standard for use with SEW-EURODRIVE’s mill drive solution.