Sun-to-Liquid technology to produce ‘solar steel’

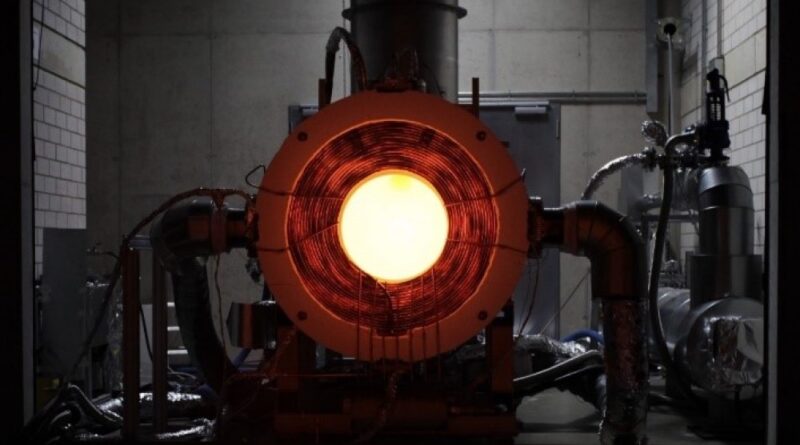

Synhelion uses solar heat to convert CO2 into synthetic fuels, so-called solar fuels. Solar radiation is reflected by the mirror field, concentrated onto the receiver, and converted into high-temperature process heat. The generated heat is fed to the thermochemical reactor that turns CO2 and H2O into syngas, a mixture of H2 and CO.

The syngas is then processed by standard gas-to-liquids technology into fuels such as gasoline, diesel, or jet fuel. Excess heat is saved in the thermal energy storage (TES) to enable continuous 24/7 operation (https://synhelion.com/technology).

While the focus will be on transportation in the beginning, the process includes solar technologies that can be transferred to other applications. In the metal producing industry, the generated renewable solar process heat, which is able to reach unprecedented temperatures beyond 1,500 degree Celsius can, for example, be used for energy-intensive processes in steel production.

“We immediately recognized the potential of this innovative process from the ETH Zürich spin-off Synhelion. Aside from the solar fuel, the technology bears many possible applications in the steel industry, for both SMS group and our customers. It also contributes to driving the green transition of the metal-producing industry forward and to creating a carbon-neutral and sustainable metals industry. The SMS Concast team is looking forward to a fruitful partnership with intense knowledge exchange,” said Dr. Stephan Feldhaus, CEO at SMS Concast.