thyssenkrupp Steel orders direct reduction plant: one of the world’s largest

thyssenkrupp Steel places an order with SMS for the engineering, delivery and construction of the first hydrogen-powered direct reduction plant at the Duisburg location. This marks the start of one of the biggest industrial decarbonization projects worldwide, which at one stroke will avoid more than 3.5 million metric tons of CO2 per year in the future.

The order volume for SMS amounts to over 1.8 billion euros, and also marks the largest single order in the history of the company. Moreover, significant additional structural building services will be required in addition to infrastructure and media connections.

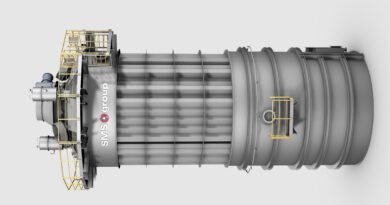

The preliminary tasks can be started immediately, under the scope for an earlier start to work that has been approved. The plant will have a capacity of 2.5 million metric tons of directly reduced iron (DRI), and is scheduled for completion by the end of 2026.

The overall project remains subject to European Union approval under state aid provisions, as well as the final funding decision. Both are expected in the coming months. The state of North Rhine-Westphalia and the German government have already signaled substantial financial support for the project.

Replacement of CO2-intensive primary steel manufacture begins

The contract award marks a decisive technological turnaround for Germany’s biggest steelmaker in its more than 200-year history: As part of the tkH2Steel transformation concept, the replacement of CO2-intensive steel production by climate-friendly technologies is now beginning.

Up to this point, coal-based hot iron production in the blast furnace always involved emitting large amounts of CO2, amounting to about 20 million metric tons per year from the Duisburg location alone. Hydrogen-based processes in direct reduction plants offer a significant basis for manufacturing carbon-neutral steel in the future.

thyssenkrupp Steel is already planning to avoid as much as 6 million metric tons of CO2 by 2030, representing well in excess of 30 percent of its emissions. The transformation to carbon-neutral production should be completed by 2045 at the latest.