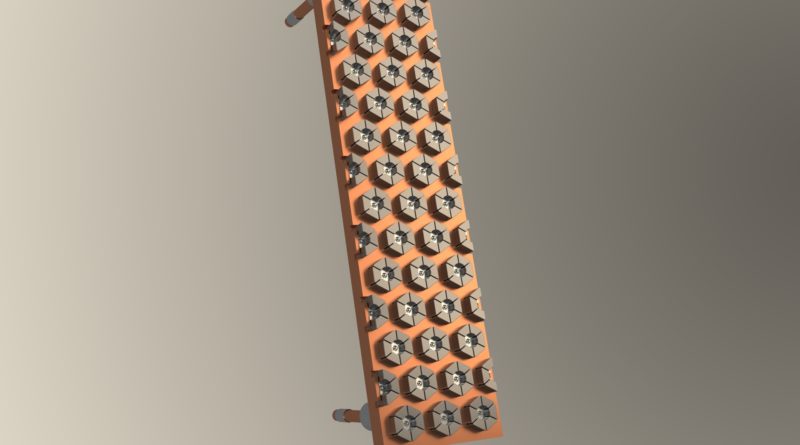

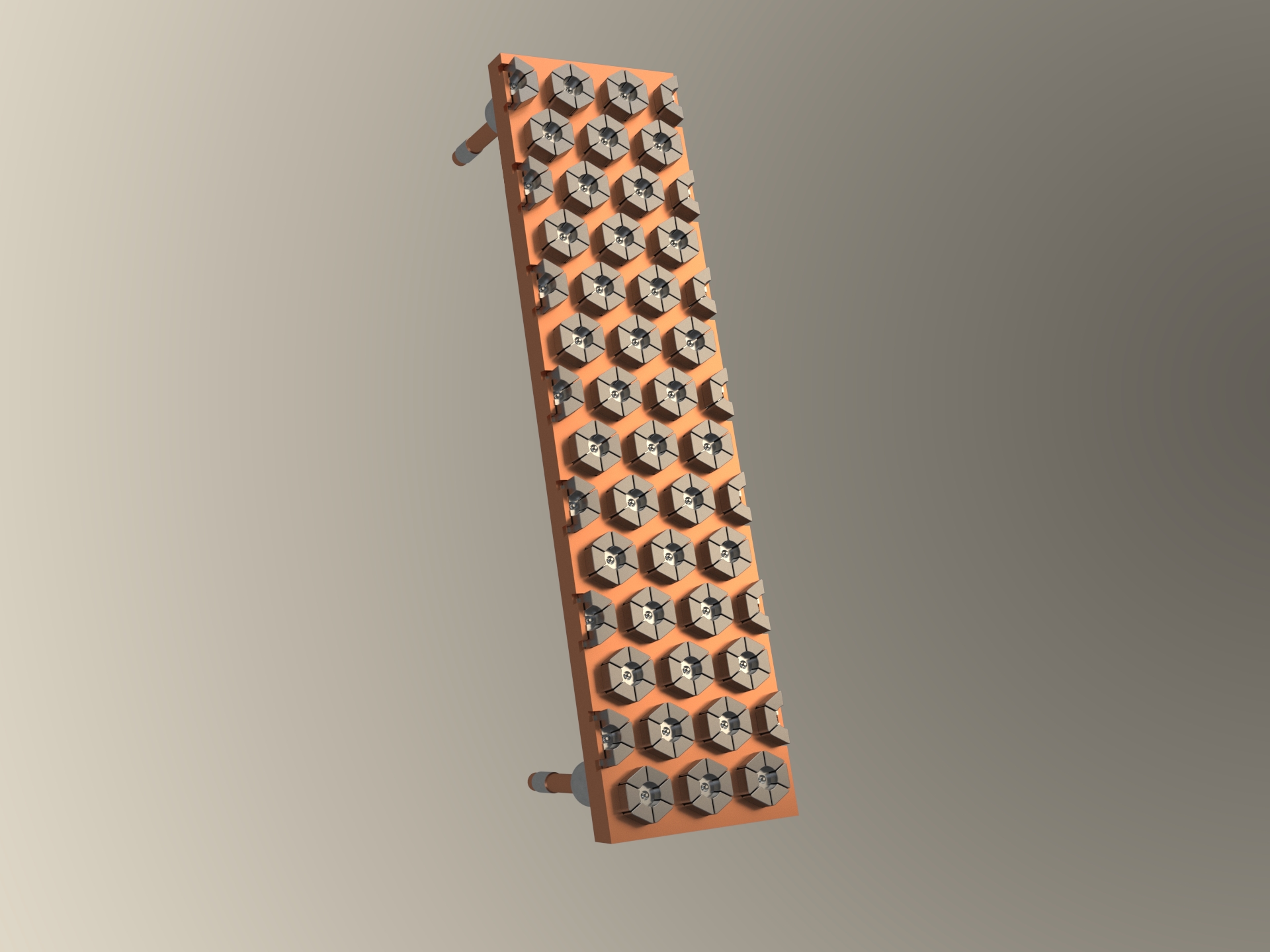

Wear-resistant copper staves for long-life blast furnace operation

- Significant reduction in wear and unplanned maintenance, prolonging campaign lifetime

- Hexagonal inserts retain burden material and encourage the formation of a self-protecting accretion layer

- New staves incorporate the patented and well-proven bend-resistant technology

- Standard as well as retro-fit solutions for new furnaces and furnace relines are available

For blast furnace operators, Primetals Technologies now offers a new type of wear-resistant copper stave. Superior burden material retention between innovative, pocket-type hexagonal inserts offers prolonged campaign lifetime by significantly reducing wear and consequential, unplanned maintenance. The staves also incorporate the patented and well-proven bend-resistant technology from Primetals Technologies. Standard as well as retro-fit solutions for new furnaces and furnace relines are available, with minimal installation and downtime requirements.

Copper stave wear is a phenomenon experienced by many blast furnace operators globally. The wear is caused by relatively cold, abrasive materials being present at the furnace walls, together with excessive forces from the descending burden. The inserts serve two functions: To create a “stone box” effect trapping in the unreduced materials when they are present, and to create a surface that encourages the formation of a self-protecting accretion layer.

Furnace operators are familiar with the various causes of wear which can lead to exposure of the stave cooling water channels and consequently, leaks into the furnace. These can potentially lead to premature loss of staves. Without significant and costly intervention this can ultimately result in furnace shell damage. Wear-resistant copper staves from Primetals Technologies offer long campaigns regardless of operating and burden conditions.

The patented and well proven anti-bending solution eliminates premature failure of the staves through prevention of stave corner bending by thermal effects. As a result, excessive movement of the cooling water pipes is limited, preventing cracking of critical weldments and detrimental loss of cooling water into the process.

As a leading supplier of blast furnace staves for over 40 years, Primetals Technologies knows that optimum furnace cooling design starts with understanding the profile of the furnace and the process conditions. With such know-how and expertise, Primetals Technologies optimizes furnace stave design to best match the varying conditions within the furnace, resulting in long-life, trouble-free operation.