Online insight into your green molding sand quality

Calderys has launched a new digital solution called CALDE® e-Support. It offers online reporting of green molding sand analysis, backed by troubleshooting and recommendations by Calderys experts.

Digitalization is now one of the defining trends within the industries – and the foundry sector is no exception. It is a means of solving the challenges that face the foundry sector.

These pain points shared by our foundry customers form the rationale behind the digital strategy at Calderys.

Why molding sand testing?

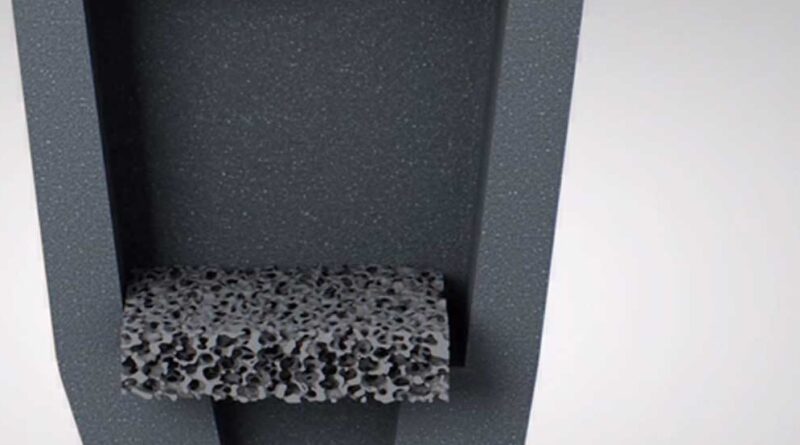

The characteristics and quality of molding sand materials – and how they change over time – are an essential component of casting quality. As a supplier of bentonite and additives for green sand molding (which is used in the process of metal casting), it is also an area that Calderys knows a lot about.

Elisabeth van den Berg, Foundry Marketing Director at Calderys, explains: “Customers regularly ask us for help understanding the quality of their molding sand materials. This information has the most value when provided quickly. Customers were also therefore asking for it to be made available online, where they could access it easily, when they needed it.”

Listening to these requirements, the idea for CALDE® e-Support was born.

“Our first aim,” continues Elisabeth, “was to meet demand for more timely reporting of molding sand test results, which we regularly undertake for our customers at our laboratories. Today these reports are emailed automatically to the customer, and we will shortly introduce a secure cloud-based portal where customers can securely access their data.”

The reports have also been standardized and include statistical analysis of trends based on the customer’s historical data.

“That brings us to the second aim of CALDE® e-Support: to facilitate continuous technical support for our customers and help them optimize their processes,” says Elisabeth. “Our reports already include troubleshooting and recommendations from a Calderys expert, and we expect this functionality to increase, as the solution evolves, to include more customized interpretation of a customer’s data, with troubleshooting tailored to their specific applications and needs.”

Customer-centric digitalization

CALDE® e-Support has now been rolled out to customers of Calderys molding sand analysis services.

“The ultimate aim of CALDE® e-Support is to allow foundries greater control of their mold and core production process and, by doing so, to improve the quality and consistency of their casting,” concludes Elisabeth. “It is a great example of what customer-centric digitalization – and what we at Calderys – are all about.”

Digital ambitions for the foundry sector

Digital solutions have a huge potential to improve casting processes and to tackle some of the foundry industry’s most pressing challenges: from improving efficiency and casting quality to reducing costs and environmental impact. Digital solutions are one of the key ways to facilitate access to skills and knowledge that may not be available in the foundries in house.

“Many industries lack access to sufficient skills and manpower. The foundry sector isn’t different,” said Elisabeth van den Berg. “Digital solutions – such as CALDE® e-Support – have the potential to open-up access to experts, who would otherwise be unavailable or require lengthy travel in order to visit the site.”

Such continuous technical support is one of five pain points encountered by our customers and that form the foundation for digital ambition at Calderys. These challenges were identified back in 2021 based on a series of interviews with key foundry customers. They were as follows:

- Ease of doing business

- Predictability

- Efficiency

- Safety and the environment

- Access to technical expertise

“These pain points provide the framework for our digital ambition at Calderys,” says Elisabeth. “All digital solutions that we develop should align with them. We continue to work to add to our applications, skills, and capabilities to drive this ambition and better serve our customers.”